When you really need a short, handy AR-15, nothing beats an SBR truck gun.

- SBRs, or Short-Barreled Rifles, require an NFA tax stamp and ATF paperwork. Don’t forget!

- Truck guns are short and handy, can be deployed quickly and pack a punch.

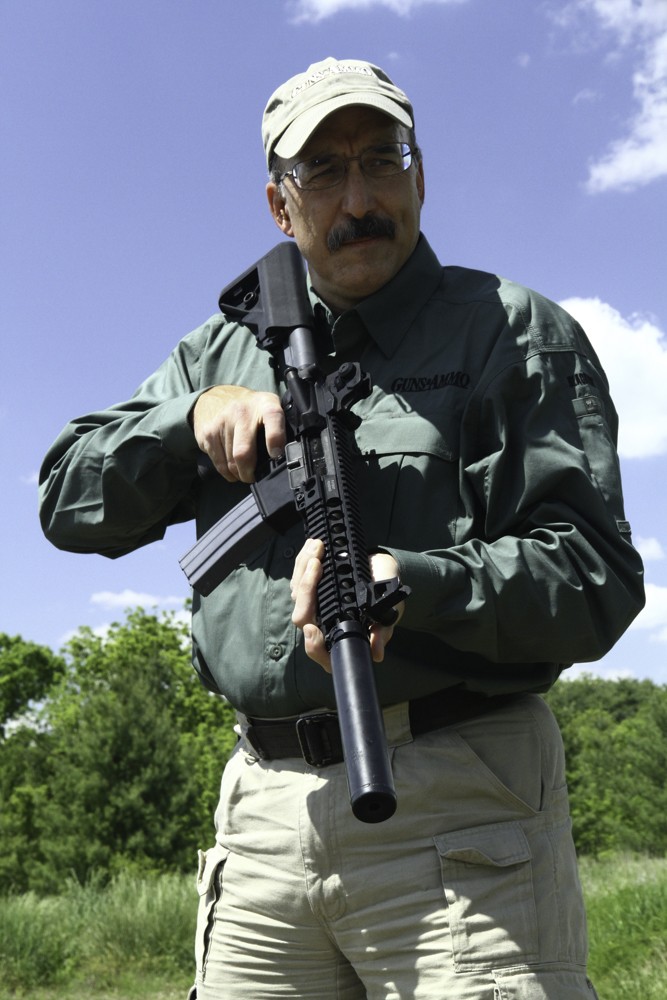

- The author used a lower from Primary Weapons Systems and upper from BCM.

Here we bite the bullet, accept that we’ll have to pay for the transfer tax, and build an honest-to-God SBR truck gun. Since we’re all-in on this, there’s no point in going half-measures on the parts and the build. So, we start by … wait a minute, we don’t start. We plan.

You cannot proceed in any way to making or buying an SBR until you have the approved form, with its tax stamp, in your grubby paws. Oh, you can have a rifle and the handguards, muzzle brake/flash hider, light, optics, etc., but you cannot have the barrel on-premises until you have the stamp.

And I’d even be leery of something cute, like having the SBR barrel, which you will install after you get the stamp, stored up at your cabin by the lake.

You still own it, have access to it, and unless the cabin is by a lake that requires an airline flight, it is easy to get to. No, do this by the book, buy the barrel only after you have the stamp.

Or, just buy the SBR, complete, but built/assembled to your specs.

Me, I grabbed one out of the rack. (To steal a line from the late Alan Rickman: “Benefits of a classical education.” In this case, years as a gun writer.)

I used an SBR lower from Primary Weapons Systems. It was built with one of their piston-system 7-inch barrels on it, and it has worked very well. It’s been reliable and accurate, but the muzzle blast is … oppressive. Seven inches is just too short, the blast is bad, and the velocity loss is too great. But boy, is it handy.

So, I replaced the upper with a BCM 11.5 slimline upper. This is a direct-impingement system, the traditional AR system.

The handguard is a free-float design, it comes directly from Bravo Company, and is called their KMR. It has KeyMod slots (you can also have M-Lok if you wish) and comes out 10 inches from the receiver, close up behind the flash hider on an 11.5-inch barrel.

It is slim, and I can really wrap my hand around it. It uses a proprietary barrel nut, and the clamping screws pass through the clearance slot in the nut, so the handguard is rigidly attached to the upper.

This was built with a BCM barrel, 11.5 inches long, and put into an M4 upper.

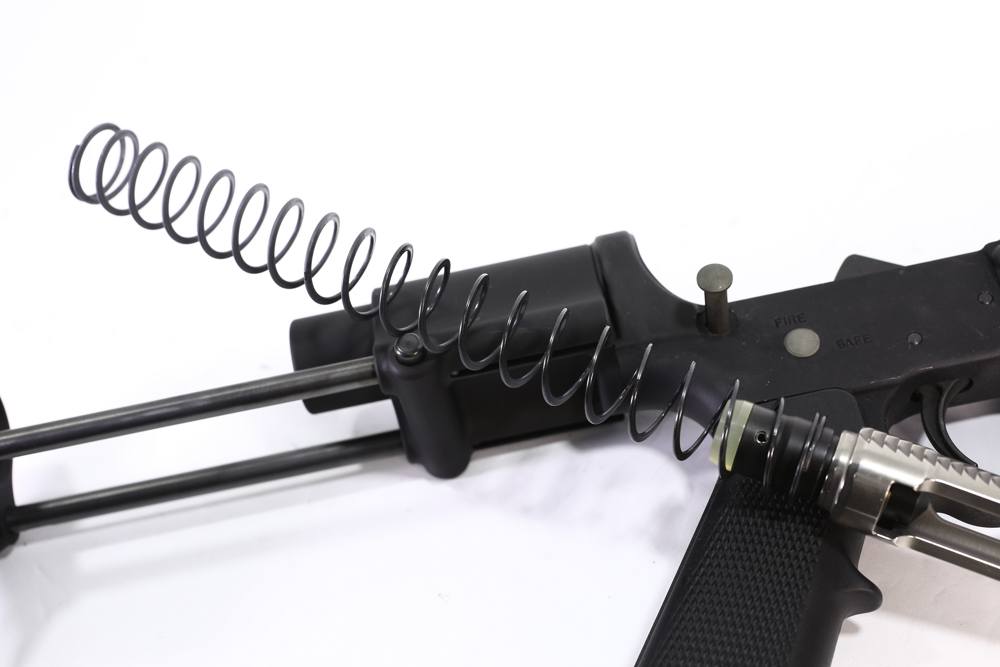

For the lower, I used an SBR’d lower, and installed the LWRC PDW stock on it. This is a telescoping stock that is the absolute shortest a stock can be. It requires a replacement carrier, since the buffer weight is pinned to the carrier. And, you have to choose between DI and piston.

The buffer tube of the LWRC PDW stock is shorter than any other, and this requires that they include a socket for your torque wrench, to reach into the housing and mesh with the castle nut teeth, to tighten the stock assembly. Once it is in place, the SBR can’t be assembled or taken apart as a hinge-open firearm.

Press both takedown pins out, and then lift and pull the upper assembly off of the lower.

To re-assemble, put the carrier and bolt into the upper, and the spring in the lower, and use the carrier tail to compress the spring back into the lower as you join the upper and lower. It is a bit involved at first, but once you learn the trick, you’re fine.

Editor’s Note: This excerpt is from Gunsmithing the AR-15: Building the Performance AR, available now at GunDigestStore.com.

Get On Target With More AR-15 Knowledge

- Affordable AR-15 Rifles – A Buyer's Guide

- AR-10 vs AR-15 – How Stoner’s Rifles Stack Up

- Upgrade Your AR-15 with the Best Parts & Accessories

- AR-15 Lower Building Tips – Putting The Internals Together

- How it Works: AR-15 Upper Assembly

- Buyer's Guide: Top AR Pistol Braces

- AR Pistol Reviews – Best Options for Any Budget

- AR-15 Caliber Guide – What Should You Chamber Your Carbine?

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)

How about providing some info about the tax stamp, like cost, process, etc.

Thanks