There's more to the AR-15 upper than a slab of forged aluminum. In its complete form, it's the heart of the rifle where much of the platform's heavy lifting is accomplished.

What Parts Compose A Complete AR-15 Upper:

- Upper Receiver

- Barrel

- Muzzle Device

- Gas Block

- Gas Tube

- Charging Handle

- Forward Assist

- Bolt Carrier

- Bolt

- Handguard

- Ejection Port Cover

The AR is not operated by magic. Little gnomes and fairies do not make the bullets go spitting out the front and empty cases to the side. Lots of other operations will be are key to the carbine's operation, but as the parts in the AR-15 upper are the most important, they come first.

Method of Operation and Safety Functions

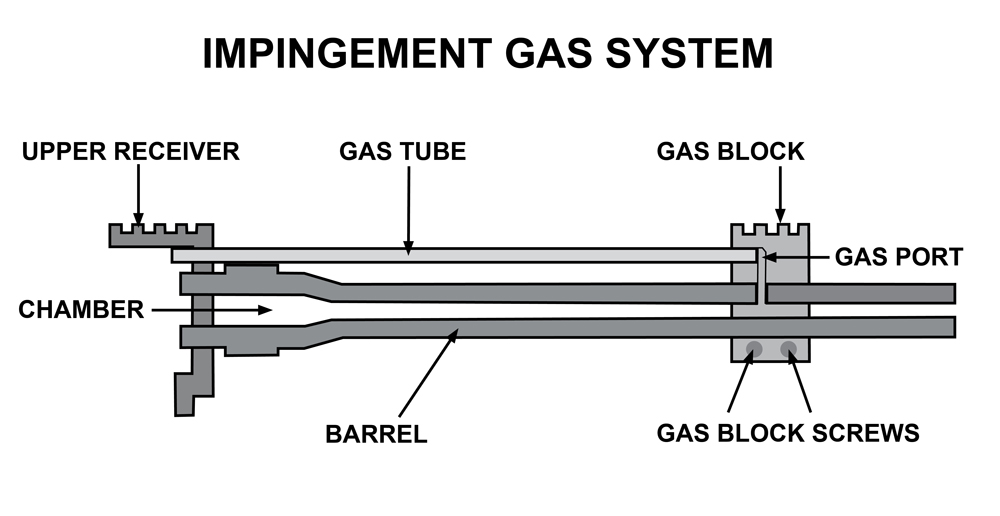

The AR-15/M16 rifles use a method of actuation known as “direct gas impingement.” That is, the gas that is vented out of the barrel (the port is under the front sight casting) is directed through the gas tube back into the upper receiver. There, it launches the carrier backwards, starting the moving portion of the cycle. Unlike other systems, where the gas pushes on a piston, the gas is vented directly into the AR's upper receiver. The advantages of the DI system are lightweight and accuracy. The obvious disadvantage is gas residue in the receiver.

Gas System

When the chambered round is fired, the bullet leaves the case and travels up the barrel, propelled by the expanding gases. The bullet passes by the gas port, and the expanding gases vent into the gas tube. There is a short time (measured in parts of a thousandth of a second) until the gas reaches the carrier key. While the bullet remains in the bore, it pressurizes the gas system. There is a short time period, from the instant when the bullet passes the gas port until it leaves the muzzle (depending on the length of barrel remaining past the gas port), when pressure builds in the system. Eventually, the bullet leaves the bore, at which time the bullet’s exit allows the pressure in the bore to drop to atmospheric pressure.

The delay of gas flow from the gas port to the key is called the “gas lag time” and the time until the bullet leaves and the internal gas pressure drops to atmospheric is the “gas dwell time.” The gas port acts as a valve, throttling the gas from the bore to the gas tube and then to the carrier. The larger the port, the sooner, and at higher pressure, the gas reaches the carrier key. Short gas lag time (the usual cause is an overly-large gas port) leads to premature bolt opening, and violent extraction. The longer the barrel is past the gas port, the longer the gas dwells against the key, increasing carrier velocity. (Using a carbine-size port on a rifle-length barrel can cause this.) Increased gas dwell time leads to harsher felt recoil, as the buffer and spring have more energy to deal with.

Get On Target With The AR:

- Go Small With These 8 Economical AR Pistol Options

- 8 Budget AR-15 Options: More Bang For The Buck

- AR-10 vs. AR-15: How Stoner’s Rifles Stack Up

- 8 Favorite Truck Gun Options For Protection On The Go

A moment here to discuss the finer points of gas flow. The assumption of many is that the gas squirts past the bullet base, through the port, and arrives at the carrier faster than the starship Enterprise. It does not; it takes a finite amount of time for the gas to travel that distance. Also, the assumption is that the gas arrives in the key with the same pressure as existed at the port. Again, not so. Increasing volume and frictional losses make the pressure in the carrier much less than that of the port bleed pressure. Were it not so, the carrier design would have to be different.

The actual pressure inside the carrier depends on a number of variables, but the biggest ones are gas tube length and the powder being used. Typically, a rifle (20-inch barrel, full-length gas tube) will have a carrier pressure of around 1,000 PSI. A carbine (16-inch barrel, short gas tube) will have pressure in the 1,500 PSI range. Conceptually, gas tube condition must have some effect, but it can’t be much. A fouled gas tube will restrict flow, but the tubes seem to be self-cleaning to a pretty effective degree.

Once the gas reaches the carrier key, it passes through the key into the carrier opening where the bolt lies. There you’ll find the carrier gas chamber, and the bolt stem and gas rings. The gas expands into the chamber, with the net effect of pushing the carrier to the rear. (Gas expands evenly, and presses with the same force, on all surfaces of a container. That is why a filled scuba bottle remains at rest. If you break the valve off, however, the gas pressure becomes unequal, and the bottle rockets away, hurling itself through the wall.)

At first glance, it might appear that the operational gases have no effect on the bolt. However, in discussing this with some AR manufacturers, it appears that the gas flowing into the carrier also impinges on the rear of the bolt. As such, it presses the bolt forward, taking some of the force off the locking lugs when the bolt unlocks – enough so that bolt service life is actually increased as a result.

On the side of the carrier are vent holes. Gas will jet out of these holes when the rifle is fired. They are part of the self-limiting nature of the gas system.

The gas presses against the interior of the carrier gas chamber, with more force to the rear of the carrier than forward, until it has overcome the inertia of the carrier’s mass, called (as before) the “carrier lag time” and the “carrier dwell time.” The sooner, and at higher pressure, the gases reach the carrier, the less the lag time and the less the dwell time. Think of the bolt and carrier as a leaky piston, in a cartridge-operated internal combustion engine.

If the gas key is loose, or the gas rings worn or missing, the system will vent too much gas before it has delivered enough energy to the carrier, and the carrier will not be pushed with enough force to overcome the buffer weight and spring. Delivering more gas (the typical response by the overly-enthusiastic “gunsmith” is to drill the gas port larger) is a poor way to solve those problems. Instead, tightening and securing the gas key, and replacing worn or missing rings, are the proper solutions.

Why is all this important? Because the AR-15/M-16 extractor is small and weakly sprung. The bolt lugs are small and heavily-loaded. Shortening the lag time of the gas and carrier, or increasing the dwell time of the gas in the carrier, causes the bolt and extractor to attempt unlocking and extracting the fired case sooner than designed.

When fired, the case expands to the size and shape of the chamber. The inherent springiness of the brass case allows it to contract from the chamber walls and back towards its original dimension (but not fully) to allow extraction. However, if the chamber pressure is too high (an over-pressure round, or poor-quality reload) the case may have been expanded too much and thus not contract enough to lose its grip on the chamber. If the system is cycled too vigorously, or too soon in the planned timing, the case will not have had time to have contracted from its fired state and it will resist extraction. The friction of case to chamber wall thus may be too great, and the extractor can slip off the rim. Or break part of the rim off. Even if the case is extracted, it may shed particles of brass from the rough treatment it has received. Those particles can build up in the chamber and locking lug recesses and eventually cause the bolt to wedge closed on a chambered round and thus stop functioning.

In the short explanation, that’s it: the gas flows, it blows the carrier off the gas tube end, the carrier drags the bolt. They compress the buffer spring, and once the energy has been completely absorbed, the spring pushes buffer, carrier and bolt back to rest. Unless, of course, you’re out of ammo, in which case the magazine locks the bolt open.

The Moving Parts Of The AR-15 Upper

The whole point of the “piston in a rifle” method of operation (indeed, of any self-loading rifle) is to fire a bullet, get the empty case out and a new cartridge in. Here are the mechanics.

Bolt Function

OK, the gas flows, the carrier gets blown off the gas tube, but what exactly is going on there? The bolt rotates, driven by the cam pin riding in its slot in the carrier. The initial rotation creates “primary extraction” where the drag of the bolt on the fired case partially rotates the case, freeing it from the friction of expanding to the chamber size. A good example of a system that lacks primary extraction is any pistol. The barrel drops down from the breechface, but the case is not otherwise broken-free from its grip on the chamber walls. The movement of the slide snatches the fired case straight back out of the chamber without first rotating it slightly to break it free from the chamber walls.

If the .223/5.56 case in the AR-15 chamber is over-expanded due to excessive pressure, or the bolt attempts rotation too soon caused by an improperly-tuned gas system, the case will not have had time to shrink from firing, and the frictional bond will not be broken between case and chamber wall. The result can be merely annoying, as the abraded case leaves brass particles in the chamber and feedway as it is rudely snatched from the chamber, particles which are also splattered on the bolt and carrier, and on the inside of the receiver. At worst, the cases will have the rims bent or broken-through, partially extracted and wandering aimlessly about the AR-15 upper receiver. Or the extractor will slip off the rim entirely, leaving the fired case in the chamber.

Ejection, Feed, Chamber, Etc., Etc.

The bolt, having pulled the case from the chamber, hands the job off. The spring-loaded ejector hurls the empty out of the receiver. The bolt-carrier assembly, pushing the buffer and spring behind it, finally runs out of steam. The buffer and spring push them back into battery, stripping a round off the magazine, shoving it in the chamber, and the final act of the carrier in its forward travel is to rotate the bolt to the locked position.

That’s all there is to it.

Editor's Note: This article is an excerpt from Gunsmithing the AR-15.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)

might be time to revise those prices at the bottom. The $350 link to PSA upper is now $550.

This story seems a little confusing. It states that m16/ar15’s use a di system. Although some more recent ar’s may use di the one I spent hours cleaning on the armory floor had a piston. Then to make it more confusing it goes on to describe a piston system including a picture of the bolt complete with integral piston. The discription of forces seem to imply that the piston has a minimal role in thrusting the bolt carrier rearward although it does say that the lugs on the bolt are unloaded for rotation. I saw no reference to the cam pin, which is actually a follower that rotates the bolt to unlock it or the unusual action of the gas cylinder moving as part of the bolt carrier while the piston stays stationary against the breech. I also wonder if the friction of the bolt against the head of the cartridge would be enough to overcome the friction of the cartridge expanded in the chamber to rotate it as described. So what’s the real story?