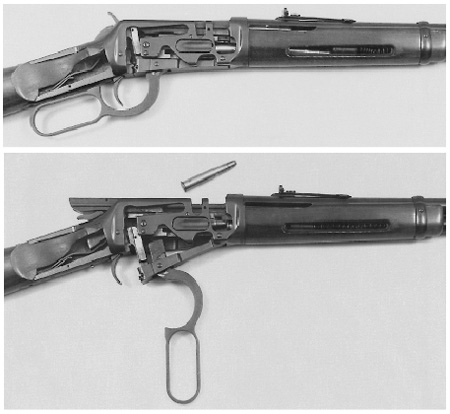

The Model 1894 incorporated a newly designed action in a light, thin-walled frame (receiver) that was quite revolutionary.

The receiver is the part of the gun that houses most of the moving parts relating to the actual chambering, firing, ejecting, and rechambering of the cartridges. This group of parts is called the “action.”

Consisting of a simple, vertically moving breech block that rises to cover the entire rear of the breech bolt when the action is closed, the system is integrated and connected by an unusual (by previous lever action standards) link/pivot system. This arrangement at once provides the necessary length of throw for a true rifle cartridge, and the strength to withstand the increase in chamber pressure and heavier bolt set-back.

Also incorporated in the action is a newly designed safety system. Utilizing a lever actuated plunger and “safety catch,” this new system physically blocks the trigger and disallows hammer fall/cartridge discharge, until the action is fully closed and locked.

Throughout the evolution of the Model 1894/94, there were many changes in receiver design. Most of them were subtle – virtually invisible on a casual inspection – but glaringly apparent upon a serious study. In this chapter I will provide in-depth detail on all the internal/external changes, and will include a comprehensive study of the takedown model.

In as much as a thorough study of markings on both the receivers and the barrels can be tedious and quite involved, and that a conscientious study of all Model 1894 markings is very important for the accurate evaluation and/or authentication of any given specimen, I’ve decided to detail and illustrate them in a separate chapter (Chapter 7).

Receivers were originally manufactured from a solid, high carbon ordnance steel forging. The “blank” forging was only a roughly shaped piece of steel, and required hundreds of separate machining operations and dozens of inspections before being inventoried as a usable part. The previous and highly acclaimed Winchester manufacturing methods, with all the usual high standards of quality and attention to details, prevailed for the Model 94.

The only changes of consequence on any of the first model/second model (through Pre-’64) versions of the receiver was the very early first/second model cartridge guide screw change, a change to the “extra steel” and “nickel steel” alloy also fairly early in the production cycle, and another and final change to “proof steel,” during the 1933-34 era.

The screw change is easily noticed and is detailed later in this chapter. The change to different alloys is also quite apparent. One can readily note the resistance to the bluing process and ultimate “flaking” problem encountered with the nickel steel frames, and the subsequent vast improvement in finish quality and durability after the introduction of the proof steel models.

As previously mentioned, the Post-64 receivers, until the introduction of the angle eject models, were “mystery metal” castings. The cutback in manufacturing steps, details, quality of finish, etc., is readily apparent in these models.

With the introduction of the angle eject series, we are pleasantly re-introduced to the 100 percent forged steel receiver, and with most of the old-time quality of workmanship returning as well. This receiver design is the latest in the series and was still in production to the end.

PRICING

The introductory pricing for the Model 1894 was about $18.00 for the carbine; $19.00 for the round-barreled rifle; $21.00 for the octagon-barreled rifle; $25.00 for a takedown round-barreled rifle; and $27.50 for a takedown octagon-barreled rifle. These prices are approximate and for standard specimens only.

METAL FINISHING

It is interesting to note that the bluing process used by Winchester was originally called “browning,” and the area of the factory where this process was accomplished was called the “Browning Shop.” While there is a method of metal finishing called browning, and in actuality it is exactly that (the metal acquires a distinct brown color), this was not a standard method employed at Winchester. True “browning” was a special order extra-cost option, and is extremely rare on any Winchester.

The bluing process was one of the many steps in manufacturing that in the early years of Model 94 production was accomplished by outside contractors.

These contractors employed many craftsmen, and most of these came with their own secret formulas and application methods. These different formulas, while being basically the same and deemed acceptable in meeting Winchester’s high standards, did produce some slight variations.

As with the variations noted in stock finishing, bluing variations will be all but undetectable on any gun that is not absolutely pristine, and then only if you have several pristine examples from different periods of manufacture to compare with each other.

Also frequently occurring in the metal finishing areas, as in the stock-maker/finisher’s department, was the “pride factor.” Parts known to be going on the higher grade guns, often received a little “extra.” Men of this era were proud craftsmen; a little more time and effort to achieve a finer polish, or an extra coat or two of bluing solution to produce a richer, deeper color, was certainly not too much to expect – it was usually done as a matter of course.

Special guns were as special to these fine gunmakers as they were to the customer.

There were three types of bluing processes employed, and each was accomplished in its own special area. Each method had its own virtues and final result, and accordingly, each was applied to specifically different parts.

One method, called rust bluing, was precisely as implied. A part was swabbed with a solution of water, ferrous chloride, mercury chloride, alcohol, copper sulphate and nitric acid (the chemical mixture could vary slightly depending on the craftsman) and was left hanging in a damp, warm room called a “humidity area.” A fine coat of rust appeared in a few hours. This “controlled oxidation” was then removed by carefully rubbing the part by hand with a very fine grade of steel wool.

To develop the richest and deepest blue-black color, it took several cycles of swabbing with the solution, allowing the part to rust, and careful rubbing with the steel wool. The final step in the process was to rinse the part in very hot water, quickly blow it dry, and while still warm, carefully coat it with a good grade of oil.

Very time consuming but very beautiful, this method was used only on barrels and some receivers. It was usually reserved for “high grade” guns but was the method of choice for all shotgun barrels.

Note: The browning process was essentially identical to rust bluing, including the chemicals used, but there was no rubbing of the parts with steel wool between the coats of solution. The rusting was allowed to slowly and evenly build up. When a nice, even dark brown color was achieved, the part was dipped in scalding water to halt the chemical reaction/oxidation process. After quickly drying from the heat of the water bath and while still warm, a good grade of oil was carefully rubbed in with a cloth. The rubbing of the cloth during the oiling removed any remaining loose rust and the part was left with a fine, smooth, dark brown finish.

A second method was variously known as machine bluing, charcoal bluing,carbon bluing, or heat bluing. Parts were placed on racks and put into an oven containing bone meal, charcoal, and either pine tar or sperm oil. The parts were heated to a temperature of between 1,200 and 1,400 degrees and left for several hours. The combination of heat and the resulting smoke produced by the various ingredients gave the parts a deep blue color. When the proper color was achieved, the parts were removed from the oven, quenched in oil, and left to dry.

Not without drawbacks, this method left the parts with an unacceptably brittle nature. To remove this brittleness, the cooled parts were returned to the oven, reheated to a moderate 500 to 700 degrees and this time left to cool naturally.

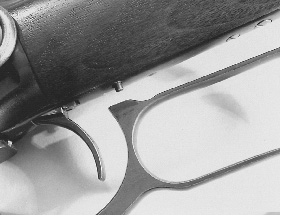

The part was now designated as heat treated or tempered, and was extremely durable. Small parts such as hammers, levers, screws, and sometimes even receivers were blued with this process.

The third process, of which there are three variations, was the immersion method. The earliest and most dangerous variation was called nitre bluing. A solution of refined nitre and 10 percent peroxide of manganese was heated to 700 to 800 degrees. The parts were immersed in this solution for about 30 minutes.

The second method, called the “DuLite” process (the solution itself was named DuLite and was developed in the late 1930s) required a solution temperature of only about 300 degrees, but required several separate immersions to achieve an acceptable color.

The third method was a “black oxide” process using a solution of large amounts of caustic soda, sodium nitrate and sodium dichromate. This was the later method employed with marginal success on the “mystery metal” receivers of the late 1970s to early 1980s.

With all three methods, when the color was acceptably dark, the parts were rinsed thoroughly in boiling water, quickly blown dry, and dipped in a bath of oil. All parts post-World War II to present are blued with the immersion method.

Winchester, to the end, was constantly re-evaluating and experimenting with finishes. Many late model factory experimental specimens (and so marked) that are found in private collections are examples of different polishing and coloring techniques that may or may not have proven acceptable.

Various types of plating, such as nickel, silver, or gold, may occasionally be found on a Model 94 receiver, as well as casehardening or “color finishing.” Any of these finishes must be considered extremely rare and unusual. Guns found with these features must be reliably documented/authenticated as original before acquiring any collectible status or value.

Casehardening/color finishing is accomplished by surrounding the selected part/parts with a mixture of bone meal, charcoal, and small bits of scrap leather or even leather dust, and packing it all into a tightly sealed container. The container is then heated red-hot for several hours. After a formulated period of time, the part is removed from the mixture and quenched immediately in water. Hardening takes place only on the very surface of the part due to carbon absorption from the superheated mixture, but the original properties of the metal below the surface are left intact. The part is wear- and rust-resistant, but not brittle.

The combination of the ingredient mixture, the heat, and the quenching procedure produces the beautifully mottled and colorful finish so prized and admired by Winchester collectors.

This is an excerpt from The Winchester Model 94, A Century of Craftsmanship, 2nd Edition.

Learn More About Legendary Winchester

- 9 Greatest Winchester Rifles And Shotguns Ever Made

- Restored To Life: Winchester 1886

- Winchester Model 12: The Perfect Pump-Action Shotgun

- Winchester Model 1897 Riot Gun

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)

im in the market to buy a pre 64 model 94 and ive noticed some very old models have the winchester name and model ingraved behind the reciever at the screw mount above the rear stock and i like that. what year did they stop doing that? any info would be helpful. thanks