Creating brass for rare and obsolete cartridges is easier than you think. Here's what you need to know to create your own at home.

What You Need To Know About Making Brass:

- Opens door to obscure and rare calibers.

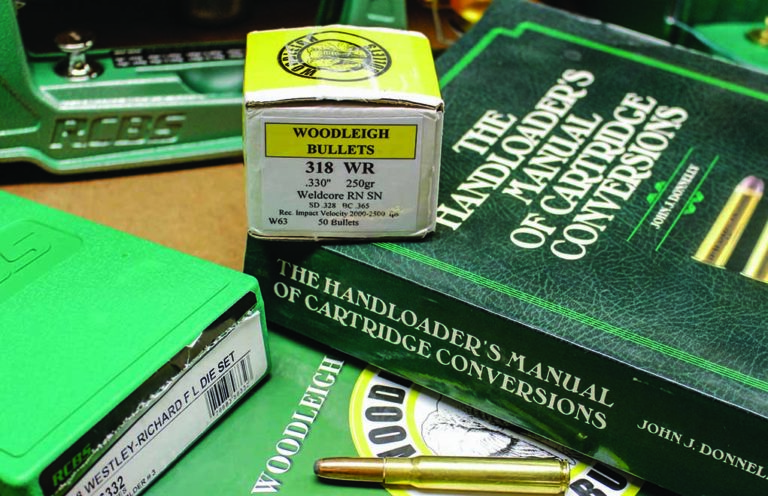

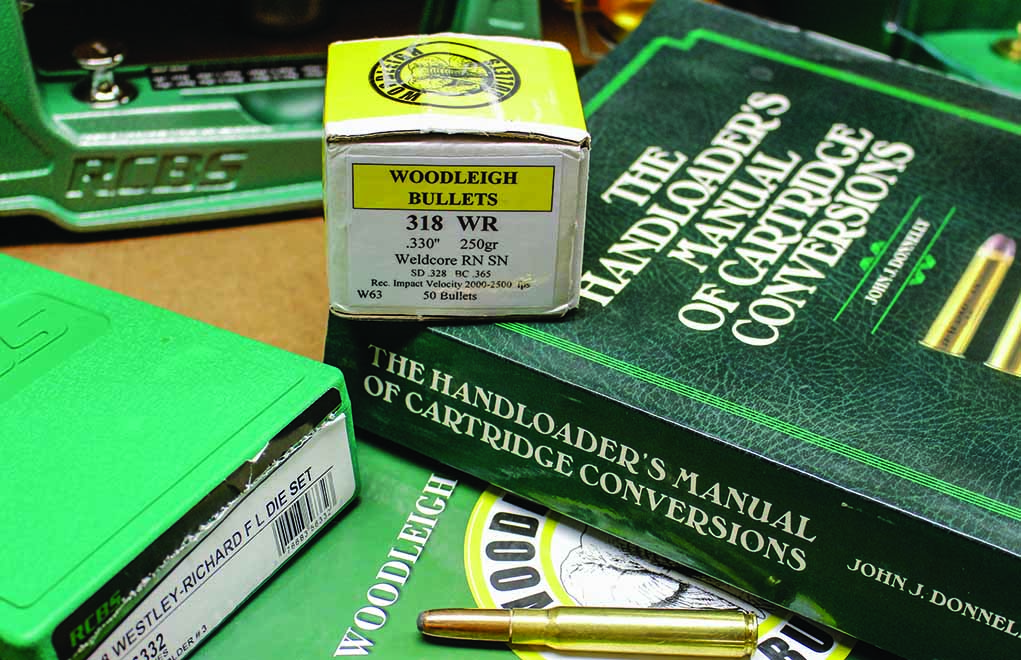

- The Handloader’s Manual of Cartridge Conversions is an indispensable tool.

- Can be as complex as removing a belt from a magnum.

- Can be as simple as resizing a cartridge's neck.

There are times when certain cartridge cases are just unavailable, if not simply unaffordable. I ran into just this situation while I was looking for ammunition for a new rifle I’m having built. I’ve had a desire to own and hunt with a .318 Westley Richards since I first began to read the classic African stories of W.D.M. ‘Karamoja’ Bell and John ‘Pondoro’ Taylor (there’s something cool about earning an African nickname, eh?) as they recounted their tales and experiences with the classic cartridges.

In all honesty, there’s really nothing revolutionary about the classic .318 Westley Richards; it shoots a .330-inch diameter bullet, with the choices being between 180-, 200- and 250-grains, depending on the manufacturer, the classic load being a 250-grain round nose at 2,400 fps muzzle velocity. The .318 WR is the older cousin to the .338-06, with the latter having a much wider selection of bullets, but the former making you want to lift your pinky in the air when you sit down to afternoon tea. At any rate, I think it’s a cool cartridge, and I am an aficionado of the classics. My rifle is still in the construction phase, going through its metamorphosis at Hillbilly Custom Rifles, and I needed some dummy ammunition to test the magazine length and the new chamber. This posed a bit of a problem: There are very few sources for .318 Westley Richards brass. The dies were no problem—RCBS makes a great set of full-length dies—and there are some good bullets on the market. I’ve chosen the Woodleigh 250-grain round nose Weldcore as an all-purpose bullet, as well as a nice 200-grain round nose from Hawk Bullets in New Jersey, which would work perfectly for deer and lighter game. But the brass…

There are a couple boutique brass producers that will make a run of properly headstamped .318 WR brass, but those runs are few and far between, not to mention expensive. There is a British company still making loaded ammunition, but at almost $10 per cartridge, that wasn’t exactly the route I wanted to take either. So, I dug out my well-thumbed-through copy of John J. Donnelly’s The Handloader’s Manual Of Cartridge Conversions a fantastic reference book that every handloader should own, and read about the process of making .318 Westley Richards brass out of good ole plentiful .30-06 Springfield brass. It wasn’t difficult at all.

More Reloading Info:

- The Flexible And Forgiving .30-06 Springfield

- The .45 Colt: A Wheelgun Classic

- .300 Win. Mag.: The Answer To Most Hunting Questions

- Tips For Reloading the .223 Remington

First, let me explain the differences between the two. The .30-06 shares a case head diameter with the 7×57 and 8×57 Mauser (0.473 inches), while the .318 WR uses a slightly smaller rim dimension of 0.464 inches, though in the past the Mauser-sized rim has worked fine in a .318 rifle’s bolt face. Since my new rifle is using the action from a 1916 Hamburg Arsenal 98 Mauser originally chambered in 8×57 Mauser, using the larger rim diameter will not pose an issue at all. The ’06 is definitely a longer case at 2.494 inches, so it would eventually need to be trimmed down to the WR’s length of 2.400 inches. I grabbed a bunch of RP .30-06 cases, used the RCBS Universal Case Prep Station to trim the brass down 0.094 inches—the micrometer adjustment worked perfectly for this—and gave the case mouths a good chamfer and deburring. Other than that, the dies would do the bulk of the work.

My RCBS resizing die has a tapered expander ball, which will work the smaller diameter neck of the ’06 brass slowly, for a smooth and consistent expansion. I used Imperial powdered neck lubricant and ran them through the RCBS .318 WR resizing die to open the necks to proper diameter, and to move the shoulder to the proper positioning. Viola! Though the headstamp read RP .30-06 Sprg., I had in my hands the first of the .318 Westley Richards cartridges that I plan to take on many adventures.

I compared them to the two example .318 WR cases I had from Quality Cartridge, and they showed to be dimensionally identical. I loaded some bullets into unprimed and uncharged cases, and sent them off to Hillbilly Rifles to make sure everything was going well with the new barreled action, and they worked just perfect.

Making brass for rare or obsolete calibers certainly isn’t something new; handloaders have been doing this for decades, and it can turn a wall-hanger rifle into a field champion once again. Sometimes the conversion is easy and only requires a single pass through a resizing die. The .318 WR above is an example, but just as easy would be making .257 Roberts brass from a 7×57 Mauser or a 6mm Remington case, or .338-06 and .35 Whelen from .30-06 brass. I’ve made ammunition for an older .30/.338 Magnum by obtaining a good set of dies with a tapered expander ball and using 7mm Remington Magnum brass. Other times a set of forming dies, which will reduce or expand the brass in smaller steps, will be required to best achieve the goal. Cases for the old .33 Winchester can be made from .45-70 Government brass, but in several steps, as the reduction from .458-inch diameter to .338-inch diameter is too radical to be accomplished in a single pass.

Some of the more advanced and radical transformations may require some advanced tools, as there are instances where a rim may need to be turned down to a different diameter, or a belt taken off in order to make something that will work. A good dial or digital caliper is a must, and like any handloading setup, the better your trimmer is, the more uniform your product will turn out. One last note: When you make brass for one cartridge from another, with a different headstamp, please be sure and keep that new ammo in a clearly marked box, with detailed notes. While I don’t think my .318 WR ammo would chamber in a .30-06 rifle, if it did and were fired, the results would be tragic, if not fatal.

I strongly suggest you grab a copy of Mr. Donnelly’s book, as it contains the formulae for making all sorts of wildcats in addition to the SAAMI accepted cartridges, as well as many of the older black powder cartridges. You never know when you may find a treasure in the form of a rare rifle in the dusty corner of your favorite gun shop, and you’ll be happy to have the ability to make your own brass.

Editor's Note: This article originally appeared in the July 2016 issue of Gun Digest the Magazine.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)

Hi Ryan,

The 9.3 x 62 is no problem. Good brass is available from Lapua in boxes of 50. Die Sets from RCBS or CH4D Shell holder as for 30-06 and you are away Good practice bullets from Speer at 270 grains. I am using Vihtavuori Powder N135 as there is no muzzle flash

This article is extremely helpful. I just purchased a 9.3x62mm Mauser. I love it. But a box of 20 is approaching $100CAD. I’m wondering if there’s a similar approach to resizing projectiles in resizing dies. .375″ to .366″. I just don’t have the experience or know how to put of such a thing. But any article you write on the subject is absolutely fascinating. I’m going to grab a copy of that book. Thanks Mr.Massaro.