Do you want more consistent handloads? Then develop a consistent cleaning regimen for your reloading equipment.

Tools for maintenancing and cleaning reloading equipment:

- Bottle Brush

- Solvent

- Rags

- Cotton Swabs

- Ultrasonic Cleaner

- Toothbrush

- Gun Oil

- Hoppe's Gun Medic

- Brake Cleaner

Reloading is such a wonderful hobby; it can be economical, educational and — I dare say — romantic to its own strange degree. The diligent hours put in at the reloading bench seem to be reverted to a simple pile of brass in a fraction of the time while seated at the shooting bench, but once you’ve got the reloading bug and have fallen down the rabbit hole, there’s no turning back. But, things back at reloading bench can get dirty, sometimes filthy, and cleaning your gear is a necessary evil.

We need to use lubricants for resizing our brass — doesn’t matter if it’s a graphite lubricant, aerosol or gel — and invariably, that lubricant and little bits of brass will end up everywhere. Shell holders, die bodies, expander balls and seating plugs can all get gunked up with a lovely amalgam of brass shavings, powder residue and lubricant. Rust can always pose an issue, especially if you live in the more humid climates, and it will be a concern if you store your dies for extended periods. It must be dealt with accordingly. Let’s examine some ideas — some obvious and some not so obvious — to keep your reloading gear clean and in top running condition.

Love For The Loaders

For the single-stage loaders, the operation can be easily halted while you clean any one of the components. For the progressive press crown, a gummed-up die can screw up the works very easily. A routine cleaning of your dies for the progressive press is a very good idea.

Redding has actually taken this into consideration, with their new Premium Die Set for handgun calibers. Using their Titanium Carbide sizing die — no lubrication is needed, and therefore less goo ends up in the die — resizing brass is a quick and simple procedure. The Special Expander Die is an eye-opener, as it uses a unique expander specifically designed to best prepare the brass cases to receive the projectile. What’s more, the expander has a proprietary coating that will not get gunked-up with brass flakes or any other dirty concoction of lube and metal filings. I like them for single-stage work, but in the progressive presses they really show their value.

Detailing Dies

Cleaning a reloading die isn’t exactly a difficult process. I like to disassemble the die, as far as I can, for cleaning. I want to remove any foreign materials, and I want to take any and all residue out of the die. You can do this with a bottle brush and some solvent, or even a rag twisted into the die, but I prefer a two-stage cleaning method.

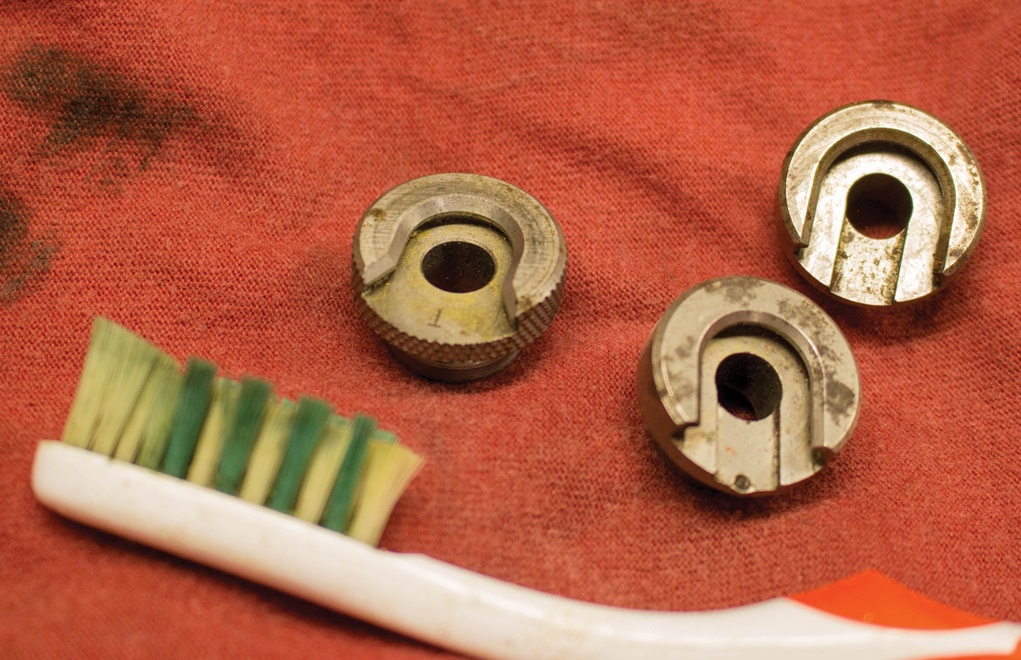

I like to use a rag or cotton swab to get the majority of the gunk out of the die body, and to remove any loose material from the rod and expander ball. Then, I give the parts a good bath in an ultrasonic cleaner; you’d be shocked as to how much material will come out of a die that you’ve just cleaned with a rag or brush. The same goes for the shell holders: The little crevices can build up that gooey mixture that has actually made placing a cartridge into them a difficulty.

Perfect Your Reloading:

- Reloading The Obsolete Cartridge

- Concentrating On Component Consistency

- Reloading: Is It Still Worthwhile?

- Bearing Surface, Pressure and Accuracy

- Does Perfect Ammo Mean Becoming A Control Freak?

I use a toothbrush to give the textured expander balls a good scrubbing, and then I start the drying and reassembly. If it’s summertime, I’ll set the dies in the hot sun to fully dry, and then reassemble, using a light gun oil to coat them, wiping off any excess. In the winter, I’ll put the dies on the heat grate to dry. Both get the job done, but I want all of the liquid solution to evaporate thoroughly.

I keep a dummy round for each bullet I use in a particular caliber, with the bullet seated to the exact depth I use. This allows me to reassemble the dies and get the seating plug very close to where it needs to be by setting it to the dummy’s length. I generally don’t move the lock rings — especially if the die is set up for roll crimping — unless things have gotten very rusty.

Rust is a problem if things are left for a while, or, if you’re like me, the salt in your hands nearly melts steel. Seriously, I can wear the bluing off a rifle on a 10-day safari, and my hands have the same effect on steel reloading dies and press parts. I save the little silica gel packs to place in the die boxes — you can find them in beef jerky packets and shoe boxes — to keep as much moisture away from my dies as possible. To keep them rust-free, I like the Hoppe’s Gun Medic cleaner/lubricant in the spray can; it’s not as sticky as RemOil, and it spreads easily. I use it on the dies and presses alike.

Stop The Presses!

Speaking of presses, I like to give them a good cleaning every now and again. The threads are definitely a place where gunk and goo can and will accumulate, and I like to take some solvent and a toothbrush to get in there and give them a good scrubbing. There’s no sense in taking all the time to clean the die bodies (and their threads as well) just to screw them into a set of grimy threads on the press.

My favorite press, the Redding T7 turret press, has more moving parts than most of the single-stage presses, and I like to clean and re-lubricate it from time to time. It requires a bit of disassembly, but I feel better once all the grime is removed from the rotating head. I like to degrease all the hinge points of a press with some good old brake cleaner, and I give it a shot of the Hoppe’s Gun Medic, or even better some M-Pro 7 gun oil (that stuff is great) to lubricate the hinges.

Polished Brass

To minimize the amount of residue and debris, I clean and polish my brass before I resize it, removing as much of the powder residue as possible before introducing the cases into the resizing die. I also use a soft, clean cotton rag to wipe off as much of the lubricant as possible after sizing. If I need to trim the cases, I use a good case brush to remove as much of the lubricant as possible, thereby keeping the seating die as clean as possible.

It may be a small factor in the overall accuracy and consistency of your ammunition, but regular cleaning extends the life of your gear, and that’s always a good thing. While I’m nowhere near as meticulous in cleaning my truck — or any other faction of life, at least according to the Mrs. — keeping my reloading gear clean is an important step in the process of developing the best ammo I can create.

Editor's Note: This article originally appeared in the July 2018 issue of Gun Digest the Magazine.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)