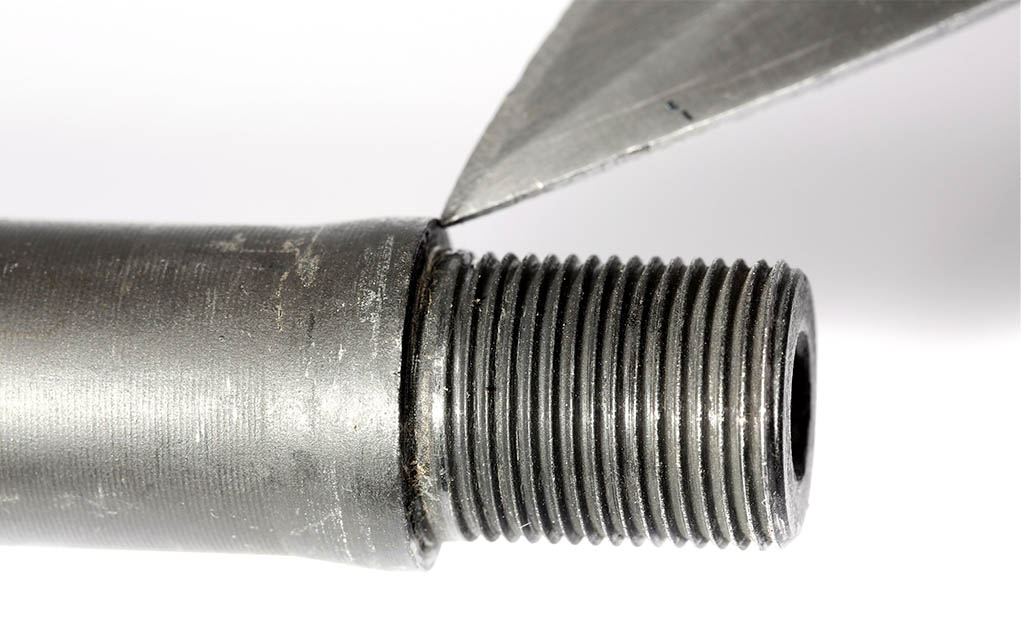

The author highlights the importance of using a suppressor alignment rod, a simple piece of steel that will save you heartache.

The best—and simplest—tool you can own for your suppressors is an alignment rod or gauge. Yes, a simple steel rod, straight and clean. Why? Because a baffle strike is no joke, and it can be expensive. Even a baffle glance. (That sounds like a line in a mystery novel: “The dame gave me a baffle glance over her shoulder.”)

The first ones I saw came from Geissele. I had to have them, so I got them. At that time, the company made them for only 5.56 and 7.62 bores, but now he offers the full range of rods, from .50 down to 5.56, with 9mm and the oddest one, 5.45, in the lineup as well. (So much for my search for the correct-diameter rods at industrial sites a few years back to make sure I had rods for all the sizes I’d need.)

Using them is easy. Make sure the rifle/pistol is unloaded, install the rod and push it until one end is flush with the front cap exit hole of your suppressor. Now look.

Is the rod perfectly centered in the exit of the cap? Life is good. Is it closer to one side but not touching? Well, you can probably get by—as long as you don’t use a bullet that’s too long for your twist. Then, life will be not-so good. (The too-long bullet might yaw really early in its travel, once having exited the muzzle, and by the time it gets to the endcap, it might be angled enough to hit the cap.)

Is the rod touching the edge of the endcap clearance hole? You’re done here; this suppressor can’t ride on this hoist until the problem is solved.

No—I mean it.

Something is wrong, and it’s probably that the threads are off-center or tilted, or the bearing shoulder of the muzzle isn’t perpendicular to the axis of the bore. You need a gunsmith with a good lathe or a machinist who understands the problem to solve it for you.

I’ve seen combos where the alignment rod scraped along the edge of the cap when inserted. Ouch. That’s a “never gonna get shot” combo, and it might not be solvable.

If you’ve invested in a suppressor alignment rod, use it. If someone wants to try your suppressor on their rifle, you gauge it. If it doesn’t pass, they don’t get to shoot—not even “Just one round, please?”

You can tell them I said so.

Every time you install your suppressor on your own rifle, be borderline OCD and gauge it. Sometimes, a bit of grit might get onto the fit and tip the suppressor. I do that every time I screw on a direct-thread suppressor, but I don’t when I’m using a QD mount system. The QD mounts have enough bearing surface and self-alignment that a bit of grit won’t matter.

But the tiny bearing shoulder on most barrels, well, that can be problematic. That’s just me. If you don’t want to do that, that’s fine … just don’t blame me later.

Yes, they cost, but what’s $75 to $125 compared to a blasted suppressor? As I’ve said many times before, this is America: You get to decide.

Editor's Note: This article originally appeared in the 2024 special suppressor issue of Gun Digest the Magazine.

More Useful Firearms Tools:

- 11 Essential Gunsmithing Tools Every Shooter Should Have

- 3D Printed Suppressor Tools

- Breakthrough Clean Technologies' MSR Carbon Removal Tool

- Upgrading Glock Iron Sights With The XS Sights Installation Tool

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)

I wonder if a caliber specific 1 piece cleaning rod would suffice? Anyone?