FIREARMS STORIES ARE generally pretty straightforward — test an item, report on the results. Not so the '70s Wunderkind, the 9mm that turned so many heads eastward, the CZ-75. The Iron Curtain and the trade barriers which protected us from it or it from us have almost disappeared; factories marketing copies and clones have arisen, prospered, and also disappeared; and while the form and function of the original pistol have become supremely well-known in the United States, this only happened because the duplicates got very good, and because reporters and analysts simply refused to give up.

It usually takes about a half-century for a firearms tale to become so tangled and ebullient; but the CZ-75 is not yet twenty years old, boasts almost as many progeny as a hyperhormonal rabbit, and still isn't common here, but it's getting that way.

If the history of the CZ-75 and its brethren seems odd and tangled, so are its roots in the Czech arms industry. For seventy years or so, Brno-marked arms produced at Ceska Zbrojovkaat Strakonica have been universally recognized as high-quality bargains.

Many of their designs have been adopted by well-established arms industries elsewhere. The British Bren began life in Czechoslovakia; likewise the British Besa. Germany, the Soviet Union, most of Eastern Europe and much of Latin America as recently as the 1950s used Czech Mausers and Czech cannon. The tendency continued whether the Czech factory was in capitalist or communist hands, Czech or German, Soviet or Czech reformist control.

From time to time, authorities in Europe and elsewhere have complained it was very difficult to sell their nationally produced firearms output when a better-made Czech product was available, despite tariffs and barriers, for about half the price. In France and Germany, from the '30s until quite recently, Czech shotguns and hunting rifles accounted for a very high percentage of products available and sold. Even now, the CZ-75 is sold in Europe quite cheaply.

Read More: CZ's Flagship – The Venerable CZ-75

This preamble is necessary because there are still some in the U.S. who describe the CZ-75 as what it is not. It has elements derived from evolved components of more ancient and/or far inferior handguns, but the slide/frame interface and most of the rest of the pistol's functional details come from the Petter-Neuhausen patents of the late 1930s.

The trigger combines beefed-up Radom geometry with a much more sophisticated base hinge spun off a Walther original. If anything in the CZ-75 seems ordinary in the 1990s, the observer should page through a GUN DIGEST from the early 1970s looking for an all-steel, double-action fifteen-shot handgun.

For the CZ-75 was and remains the original “Super-Nine,” and European pistolsmiths who've been working with the gun for more than fifteen years still believe it's the one with the most potential for truly precise shooting in the real or simulated combat arenas.

All of which is amazing, after all this time and after the fact that nearly every firearms firm in the world with the capacity to do so has produced and sold at least one gun either inspired by or is a direct copy of the Czech original. This kind of market impact is precisely what was intended by the gun's designers; for the CZ-75 was conceived, designed and sold with virtually no domestic civilian or military market. The guns have seen military use worldwide, but virtually always as an individual's private purchase. And they sell to this day in that most personal and competitive market.

I said the real market history of the pistol was tangled and confused. It is, in fact, so tangled that, by the time this sees ink, much will have changed. This is only the story of the earliest days of CZ-75, and its early clones and stepchildren.

I had to wait only ten days to get my first CZ-75 from P.I.M.C. back in 1986, but I was terribly impatient anyway because I had been waiting, in real terms, eleven long years. Tariffs, import restrictions on “Communist Bloc” products, a crazy quilt of erratic importers and undelivered product, and lots of promises had preceded my order and kept the pistol from me. Enticing ads for the gun in Deutsches Waffen Journal and the Swiss Waffen Digest- for less than half the wholesale price I paid, mind you — had held my attention.

At one point, I had even made elaborate arrangements with a German firm to acquire a Peter F. Stahl-modified custom gun, a deal which fell apart, congealed again, fell apart again, and finally, became real in early 1991, when I took delivery of the gun and owned it for two days, total. A fellow shooter decided he couldn't live without it and, like many who wind up with CZ-75s, gobbled it up with a few too many dollars before I even got a chance to properly photograph it.

By then, of course, I had too much time and money in the pistol, and no matter what it did for me, it couldn't possibly have satisfied me.

The same was essentially true of that first 1986 baked-enamel gun. By the time it actually showed up, praise and promises had me anticipating some sort of model of perfection which would do more or less everything, including assist me in leaping tall buildings in a single bound.

I'd heard the double-action pull was smooth, slick, and truly useful; and it was, at what my weights told me was about 14 pounds, through it felt lighter. Butter smooth and predictable, I eventually slicked it a bit more with careful stone and fitting work, once the gun was broken in. I had heard the CZ-75 was beautifully made.

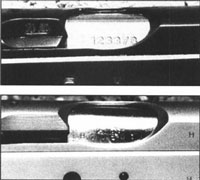

This was mostly true, though the barrel fit was very average. To say, however, I hate paint finishes on handguns is something of an understatement; phosphated underneath, the baked-on look is my least favorite finish, ranking somewhere after rust. The magazines were crudely scratched with the pistol's serial number. Sights were decent, but nothing special.

That pistol was one of a batch imported by and marked “Bauska.” The finish is sometimes referred to as “military gloss”.and if I'd had a surefire way to cleanly strip it off without damaging anything, I'd have been down to the phosphate more or less instantly. It's too hard, therefore brittle, and chips badly.

The single-action trigger broke neatly at 41/2 pounds, preceded by the gentle “takeup” – calling it “creep” suggests more tension than there really is – so common on today's semi-autos. Despite excellent overall conformance to the gun's specifications, the long wait and the opportunity to handle so many slick and graceful 9mm guns since the mid-'70s had me in a mindset to be at least slightly dissatisfied no matter what.

I sat down with the instructions and test target to do some studying. Part of the reason European guns function so well is their detailed testing and proofing. One of the tougher requirements in the Czech factory is the final approval, which requires a signature and the test target, also requiring a signature. Comrade Bobcik did mine. What I, for a long time, thought was six rounds on paper was in fact ten. Very disturbing, however, was the fact that there were two very tight groups — one dead-center and tiny, another 21/2 inches away, tight, at about 1 o'clock — and a single bullet hole, fully 51/4 inches from center at 4 o'clock, completely out of the black on the 25-meter test target. Two groups and a flyer. Ah, well, I thought, probably strange ammo or bad shooting. At the time, I hadn't even a single inkle that the pistol would replicate that pattern as long as the original barrel remained in place. Later fiddling with a Tanfoglio barrel partially exorcised the demon, but fitting a tight match barrel eventually did the job. But it was aggravating.

Detailed study of the gun's innards and bore with high magnification equipment showed a lot of very atypical attention to detail and some unusual processes used in the gun's fabrication, part of which I'm still pondering. The bore was exceptionally bright, its finish approximating a #8 R.M.S. finish. The slide and frame appear to be extremely high-quality investment casting, though the exporter, Merkuria, claims all parts are forged.

Some of the internal machining of the slide and especially the frame left no “tracks” even under very high magnification, and so the amount of machine-induced stress in the metal's crystalline structure proved to be very low. Some extremely gentle process or treatment is used on these parts, which may be worked hot or cold, or manipulated electronically or robotically; none of the machinists I talked to could really provide much insight, though the one who said, half jokingly, “maybe it's a laser” may have been closer than he knew.

I did some measuring and checking on the barrel, and at least in this gun, it's configured more like an American tube than a typical European unit. Six grooves, right twist, roughly one turn in 10 inches (probably four per meter). But the hood and muzzle fit were well-executed, clean, loose. This is done on many semi-automatics today because manufacturers know that nothing irritates consumers more than unreliable equipment, and nothing causes more fouling/dirt malfunctions than excessively tight fit on a semi-auto.

But I keep my guns well-lubricated with MDS/graphite greases and cleaner than my plates or silverware, I do not shoot in pigpens, and I demand accuracy, even at the cost of some reliability. The barrel leade cut ahead of the smooth chamber appeared to have a sharper step than I am accustomed to seeing in European semi-automatics, and I suspected this could cause problems with some fatter-nosed hollowpoints.

Determined to leave the gun in a factory-stock condition for initial testing, I still went ahead with some steps I execute with all semi-automatics. My good friend and pistol-smith John Student taught me to check everything, prevent “unexplained” problems as I work, gently polishing and closely studying parts. I merely detail polished the mainspring, recoil spring, firing pin and firing pin spring with gentle touches of 600-grit emery cloth and, afterward, pumice and oil and a silicone cloth. One removes virtually no functioning metal in these processes.

I then packed the mainspring and firing pin with heavy grease and reassembled. Contrary to advice from some smiths, modern MDS greases remain viable at very low temperatures and do not migrate all over your pistol, holster and clothing, as oil does; and the lubricity of modern greases is superb, preventing corrosion in areas one cannot reach without tearing the gun apart.

The general takedown procedure is simple, and the trigger assembly is much easier to deal with than the Hi-Power or Model 1911 because it's semi-modular. There is no magazine disconnector/safety. There is nothing in this pistol of fragile design, and there are no sheet metal stirrups in the trigger mechanism.

The safety and slide stop on the CZ-75 and most of the current generation of clones are located on the same plane at the pistol's left. The newer CZ-85 is ambidextrous, and I've seen a European 30-caliber (7.65mm) pistol equipped with smooth, handsome wood grips and gracefully extended controls. Who knows what the future might hold?

In several thousand rounds of firing, no “regular” jams of any sort have been encountered with the CZ-75. With the original barrel, some failures to fully chamber were encountered with jacketed hollow-points conflicting slightly with the leade.

Also digested by the CZ-75 were vast quantities of surplus ammunition. And herein lies a wonderful tale. Most European ammo for 9mm is at or slightly above the old SAAMI 9mm specification, and virtually all American ammo well below the so-called “redline.” NATO specifications for the cartridge are very hot by U.S. civilian standards, normal to soft by European specifications, so I hoard Greco, Norma, Lapua and Fiocchi 9mm loads. When I could still afford Lugers, I was pleased to take a superb Artillery Model for minimal money from an owner who, though advised properly, refused to shoot either European ammo or “warmish” handloads, and who was therefore convinced his gun just didn't work. Didn't work? I put 5000 rounds through it without a single malfunction. The CZ-75, especially with the Geco and Fiocchi loads, was more than accurate enough to save anyone's life; the groups thus made were essentially miniatures of Comrade Bobcik's work.

Later, with the match barrel fitted, the flyers totally disappeared. And the pistol, across a padded rest or from a Ransom rest, began to perform brilliantly. Groups of just 1 inch at 25 yards were about maximum, and with carefully controlled handloads, Geco, Fiocchi, Norma, and Federal Match, groups became ragged bullet holes. The key to this is simple, and it was about what I had expected thousands of rounds earlier: slide/frame interface on my specimen – and on all the Czech 75s I've examined – is near perfect. Only “service” barrel fit retards performance.

The “Bobcik Syndrome” was solved by the installation of $160 worth of barrel. But I'd rather it hadn't been necessary. Proof that it would be was early on, for installing the Tanfoglio-produced barrel from my TZ-75 alleviated the flyers. And the Stahl-prepared match pistol shot about the same from day one.

Looking back, I was displeased with the CZ-75 early on mainly because, in the 1980s, I had handled and tested the big-magazine Astras and Stars, Steyrs and Llamas, Bernardellis, Berettas, the Walther P-88, every one of which either aped the Czech gun or was inspired by it. And, of course, I paid over twice what the CZ sells for in Europe.

It has proven durable and, at long last, accurate. The CZ-75 contains not a single part or system not adapted from another firearm, but it's not really a copy of anything.

Known in the '50s and '60s for a set of competent but rather boring pocket semi-automatics, Fratelli Tanfoglio then made new inroads in manufacturing firearms clones and have found the horses to market their output. From F.I.E. and ExCam's early efforts to current output from a half-dozen firms, virtually all the CZ-75 clones use Tanfoglio-produced parts and are often Tanfoglio-produced and finished guns.

I've done most of my testing of CZ-75 clones with guns from the defunct F.I.E. line. European American Armory of Florida marketed many of the same models under the Witness name, and their literature showed guns in 9mm, 41 AE, 40 S&W and 45. Springfield's P9 came in many versions; it, too, had Tanfoglio parts, though in an American-finished and assembled configuration. The Action Arms AT-84 and AT-88 employ Tanfoglio parts, but were Swiss-assembled and finished. It's all part of the CZ-75 story.

Why clone guns? Historically, there have always been several reasons. Often, the original is too expensive. Sometimes – especially so in the CZ-75's case – the original is hard to get for political/competitive reasons. Sometimes, desirable options aren't available on the original. Tanfoglio got into this market smart and early. Some of those early blued guns were misfitted and displayed odd metallurgical anomalies which led to early failures. The hard-chromed pistols, however, quickly established an excellent reputation, for the hard, flexible “crust” of their finish concealed mediocre materials. By late '86, the guns were vastly improved, and by '88, the high-mounted firing pin safety had been replaced by a unit similar to the Czech original, target and compensated versions were on the market and, as nearly as anyone could tell, the F.I.E. TZ series and ExCam's TA pistols were prospering and proliferating.

All the Tanfoglio guns sport better sights than the Czech originals. Prices were much lower. Finish options and combinations could teach anybody a lesson. The Millett-style sights on the match gun are, simply put, wonderful. And the internal manufacturing techniques are as sophisticated as the Czech guns. The externals are at least as well done. Slide/frame interface is not quite as good, but is easily adjusted in a press.

In shooting all the variants, including a couple of custom guns, some interesting information developed. A TA90C purchased after ExCam ceased to exist shot better than any of the other stock pistols, including the big match gun. It was largely a case of better-than-average frame/slide fit and a barrel that happened to be very tight. Another gun of the same model wouldn't shoot close to that particular example.

Most stock guns delivered 3- to 31/2-inch groups with most factory loads at 25 yards, but the little TA90C, carefully rested and shot with Federal Match or careful handloads, cut group size in half. All the Czech-built and Czech-inspired pistols handle and balance well, owing to the dished out tang area of the back-strap, but the Tanfoglios run a little deeper and feel a bit better. Among all the Italian and Czech pistols – and for that matter, later with the AT-84 – there were no malfunctions at all.

I preferred the high-set firing pin safety, mostly because I'm accustomed to the Walther P-38, but I seem to be the only person on the planet who does. That may account for the fact that all the recent pistols have returned to the original's frame-mounted conventional safety.

Double action on most guns evinced a 17- to 20-pound pull, which I was able to modify gradually to a smooth 9 to 12 pounds on two specimens which particularly irritated me. I am finally beginning to use the double action properly, by the way, and now that I'm accustomed to the varying pulls, the “grip readjustment” which is supposed to cause round one and two to land in different places just doesn't happen. The recurved combat trigger guard is one of those which can actually be used without drawing blood, unlike many that are beautifully covered with razor-sharp checkering. Single action on all guns was very like the CZ-75.

Almost all Tanfoglio guns use a recoil guide rod similar to those used by custom pistolsmiths, projecting through a hole in the slide. Whether these actually do much of anything is moot, but they generally make operations smooth and are easy to strip. Unfortunately, it is not easy to replace grips on any of the guns in this whole family from standard items.

All the Tanfoglio-produced and finished guns have netted me good performance at very reasonable prices. And the eight years of continuous improvement is indeed an impressive record.

Tanfoglio is, of course, neither the beginning nor the end of the CZ-75 story. Even the Chinese are producing a CZ-75 clone, Norinco's China Sports NZ-75. John Slough Armorers in England produce a pistol called the SpitFire which appears from photos to be a clone or near clone. But the best CZ-75 clone I've handled and tested so far came from Action Arms, the late, lamented AT-84.

Just the words “made in Switzerland” can pole-vault the price of almost anything into the low stratosphere. SIG knows this, which is why their recent service pistols are actually built by Sauer in Germany. But the Swiss also have high internal industrial standards, and they fancy their machine-tool quality.

Swiss firearms have been rather strange for a long time. The Schmidt-Rubin straight-pull rifles, even the recent StG-57, are oddly configured and unusually built, but incredibly accurate. The SIG-Neuhausen P-210s specifications don't outdazzle any 9mms of the '30s or '40s, let alone the '90s, but none will outshoot it. Their guns seem to be designed for a system where cleaning weapons is almost an obsession and where everyone is essentially a well-informed technocrat. My pistol sold for a little more than the CZ-75. It was money well spent.

General fit, finish and machine work were exceptional. I began to get the feeling that AT-84 was a seriously excellent pistol, or that mine was a specially prepared ringer, so I ran up to Mandall's in Scottsdale, Arizona, the only store I know that stocks several of most anything, and was able to confirm by measurement and eyeball that they're all beautifully made.

I tested for roundness, uniformity of fit, left-right symmetry, and parallelism of major surfaces on slide and frame and their relationship to each other. Everything was close to perfect. In fact, I did not adjust the trigger or polish the springs on this gun, as I am inclined to do on others; that work was pretty much already done. It was so well-fitted I began to wonder if it might malfunction without dirt or heat.

I needn't have worried. There were no malfunctions of any kind in 2500 rounds. After my most recent tear-down, even my 20x viewing glass could find no galling or abrasion in the slide/frame interface. Barrel fit was the tightest of all these pistols, which may account for the tiny down-range groups. The first ammo shot was RIO-CBC and cheap Egyptian surplus, and both gave tiny groups shooting very casually. So the theory of good fit equalling good accuracy is borne out.

My nephew greatly admired this pistol, and he wound up with it. Otherwise, I'd probably never have found out that all these pistols fit easily into leather for the Government Model and/or Beretta 92, for Bob immediately ordered an expensive Lawrence (G&G) shoulder holster, and what arrived, from the imprinted codes, was a very nice rig set up for the 92F.

And it worked and fit well, though as I advised my nephew only phoney-baloney movie detectives actually ever really use shoulder holsters, especially under their clothes. However, after only a few months' instruction, he figured out how to get it on, after which he, too, used only the companion belt holster, also from Lawrence.

For a while, and almost by default, Springfield Armory was in a position to ship more CZ-75 clones and variants than anyone else. However, the General Agreement on Tariffs and Trade allows the government to lift politically motivated trade barriers and/or to extend to any nation the MFN (most favored nation) status which largely eliminates tariffs and duties on products from the country specified. Which is another way of saying that the CZ-75 in its original Czech form is here and so is the CZ-85.

Editor's Note: This article is from the 1997 Gun Digest book.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)

[…] Read More: The Complete History of the CZ-75 and it's Early Clones […]

[…] copy of the Czech CZ-75, the Jericho 941 is mechanically identical. Magazines are interchangeable between the two in their […]

[…] copy of the Czech CZ-75, the Jericho 941 is mechanically identical. Magazines are interchangeable between the two in their […]

[…] of Solitary Motion Army and 1911 riffs inflammation the marketplace. There is a whole story about CZ-75 clones and how they multiplied like fleas on a feral pet dog. Sufficed to say, its proliferation is a […]

[…] of Single Action Army and 1911 riffs swelling the market. There’s a whole story about CZ-75 clones and how they multiplied like fleas on a feral dog. Sufficed to say, its proliferation is a […]

Still a great article to read. I had several EAA Tanfolio’s in Kalifornia that were purchased before the Feinstein BS started. Both were very accurate and well made. I had to eventually sell them to another FFL because Feinstein Laws would not allow me to transfer them off my FFL to myself. I’ve always had high regard for the CZ 75. Simple, well made, accurate and rugged. I have never seen a bad finish on a CZ 75 except for a beat up surplus one that showed some hard use. I now have a TriStar clone, the full size all steel S 120. That Turkish clone is also well made, accurate and rugged. It has a black cerakote finish that was applied in a very professional manner.

I feel that the Turkish clones will catch on with the shooting public.

[…] out-of-the-box race guns and with compact carry CZ clones. They went through several US importers; Jim Thompson tells the early clone history in this 1997 Gun Digest article. Tanfoglio also exported parts in white and provided the basis of many a new company’s or […]

[…] out-of-the-box race guns and with compact carry CZ clones. They went through several US importers; Jim Thompson tells the early clone history in this 1997 Gun Digest article. Tanfoglio also exported parts in white and provided the basis of many a new company’s or […]

I’ve had a CZ75B w/Omega trigger for almost 5 years. I will say this, it is well worth the money spent for it. It may not have the finest finish, but they are reliable and accurate. Sure it came with cheap plastic grip panels, so I replaced them with CZ 1/2 stippled Coco Bolo wood, awesome. I have shot many varieties of 380, 9, 40, 45 caliber handguns and the CZ is one of the most accurate and easiest to put down for months at a time and come back to and be accurate with instantly. Have not had one malfunction of any type. Compared to other 9’s of similar size it is a steal all the way around, for what they cost to purchase and maintain. If you don’t want a full size, they have the 75B Compact in 9mm which is equally comfortable (if not more, for me at least) and same reliability and accuracy. If you want a low cost 9mm, I would suggest checking them out.

The original CZ 75 (before they cheapened it) was a good gun despite is cheap cast frame. When it was cheapened into the CZ80 they did away with the firing pin plate and replaced it with a cheap sheet roll metal pin which resulted in the pin breaking when it was dry fired. They still give you a bag full of plasticky snap caps to use if you want to dry fire it. Next came the el-cheapo plasticky op-rod. Mine was so crappy it bent when you retracted the slide. It just about made me barf. I replaced it with a custom steel op-rod but there was nothing I could do about the el-cheapo sheet metal roll pin that holds in the firing pin (sometimes when it does not break).

The trigger pull on my original CZ75 as well as on my el-cheapo Cz85 compact is very gritty but I live with it.

Taking the slide stop pin out is a real trip if you never have done it. I have to press the protruding pin hard against the projection of my wood shop bench just to get it to move out. Not one of CZ’s better ideas for sure.

Trigger reach is very long even for a person like me that has very long fingers.

The safety on my el-cheapo CZ85 is not positive as is on my CZ75 so I cannot trust the safety to stay on with my CZ85.

The finish on both guns is not a beautiful polished blue but a crappy looking painted finish. It is more rust resistant (until it wears off) than a standard old fashioned high polished blue finish which in the cut rate firearms industry has become a thing of the past unlike back in the good old days when you could buy a quality pistol at a reasonable price. Now its sky high prices even for junk plasticky pistols. But the average gun buyer today would not recognize a quality firearm today if said firearm walked up and shot him in the foot.

I’ve had a CZ 75 SENT 1975 DEC FIRED MORE THAN 40,000 RDS THUR IT WORN OUT 4 BARRELS AND 24 RECOIL SPRINGS AND IT KEEPS WORKING!

YOU HAVE KNOW IDEA WHAT THEY CAN DO. TAKE OF CARE OF YOUR FIREARM IT CAN SAVE YOUR ASS AT, THAT TIME IT BECOME A WEAPON!

BUT REVERTS BACK TO A FIREARM WHEN USE FOR ENJOYMENT OF TARGET SHOOTING.

SO QUIT CALLING FIREARMS, WEAPONS. YOU PEOPLE ARE OUR WORST FOE AGAINST RIGHT WING IDIOT’S