Weatherby partnered with Krieger to improve the rifle that made Roy Weatherby famous.

How the Krieger Custom Rifle is a cut above the rest:

- 26-inch fluted barrel from Krieger.

- Cut rifling.

- Weatherby Mark V action.

- Oversized bolt knob.

- Cerakote finished metal.

- Hand-laid stock with an aluminum bedding block.

- LXX adjustable trigger.

The color grabs you first. Not the matte-black, gel-finished synthetic stock, but the metal. Barrel, receiver and bottom metal wear Cerakote, in flat dark earth that borders on bronze. Barrel flutes and bolt (body, shroud and handle) are black. All told, it’s a fresh, striking look. The oversize bolt knob catches your eye, too. Semi-gloss black and profiled for a perfect cosmetic fit, it’s faster and more positive in operation than Weatherby’s standard knob. And to top it all off, the floorplate wears a distinctive KCR logo that adds to the rugged elegance.

What you can’t see also defines the Krieger Custom Rifle. Its hand-laid stock boasts a long alloy bedding block for increased rigidity and more uniform action-stock seating. Last year, Weatherby tweaked the profile of all Mark V stocks, reducing grip circumference, adding a right-side palm swell and giving the forend a sharper, slimmer profile. They’re subtle changes, but palpable. The LXX trigger (for the firm’s 70th year) is also a recent upgrade: It now has a wider face, is factory set at 3.5 pounds and the pull adjusts down to 2.5 pounds.

Most distinctive is the KCR’s fluted, 26-inch barrel. Of medium contour, it’s manufactured and cut-rifled to .0001-inch groove tolerance in the shop of ace barrel-maker John Krieger. The bore is hand-lapped to 16 micro-inches in the direction of bullet travel, the muzzle threads get a protective cap and the barrel is cryogenically treated there, too.

“Boring and rifling impose stresses on barrel steel,” Pete Paulin told me many moons ago. “Deep freezing relieves them. During bullet launch, a barrel expands radially and in length. Cryogenic treatment eliminates forces that skew expansion and contraction.”

While the principle has been used since 1940, he explained, it didn’t become practical for barrels until he refined a process in 1992. It begins with a bath at -300 degrees Fahrenheit (absolute zero, or 0 degrees Kelvin, is -457 degrees Fahrenheit). Slow cooling prevents cracking. Like Paulin, John Krieger says “cryo” is no sure fix for ho-hum groups, but it won’t cause any damage and often improves accuracy.

The idea for a Mark V with a cut-rifled Krieger barrel came by way of Adam Weatherby, now the company’s CEO, on a visit to the Krieger shop early in 2017. John readily agreed to send finished barrels, bored to Weatherby’s specs, to its headquarters and assembly center in Paso Robles. But they aren’t the first Kriegers on Weatherby rifles. In fact, button-rifled Criterion barrels, once a Krieger product, have been installed on Weatherbys since 1999 and are standard on Mark Vs now.

It’s All About The Barrel

Rifling a bore can be done with a cutter, a button or a hammer-forging machine. The cutter was developed in Nuremburg in the late 15th century. It’s a small hook in a hard, bore-diameter steel cylinder. Most commonly now, a rod pulls the hook, removing a very thin slice of barrel wall with each pass. The rod indexes to deepen each groove, and the cutter’s rotation setting determines rate of twist.

“A single-point cutter imposes little stress on the blank,” John Krieger says. “But the process is slow.” Like leather seats in a fine automobile, cut rifling pairs with upscale custom rifles. It’s also standard in test barrels Krieger supplies to the ammunition industry manufacturers.

Much faster is the tungsten-carbide button. Mounted on a high-tensile rod and rotated by a head set to the desired twist, the button is pushed or pulled through the finished bore by a hydraulic ram, “ironing in” grooves. The most popular rifling option for .22 rimfires, buttons have an advocate in Steve Dahlke, who by 1982 was making barrels for John Krieger. Now president of the separate Criterion shop, he also supplies buttoned centerfire barrels.

Hammer-forging, pioneered on barrels for German MG 42 machine guns, is also speedy. A short, thick barrel blank is fed into the maw of a machine that costs more than the annual GDP of Angola. The machine “kneads” the blank around a mandrel that, like a button, wears rifling in reverse. The hammering produces a terrific din, and enough floor vibration to stagger a horse.

The barrel emerges about 30 percent longer via this process. Its slick bore has finished dimensions, though radial stresses can be hard to remove. Roy Weatherby may have been the first American rifle-maker to hawk hammer-forged barrels, later standard on Mark V rifles.

As for twist rate, “it’s better to over-stabilize a bullet than give it too slow a spin,” John Krieger says. “Lead-free bullets and those with thick jackets are longer than soft-points hunters used 50 years ago, and they require sharper twist.”

Accuracy Through Action

Accuracy starts before the bullet meets rifling. A parallel throat acts like a piston sleeve: It must allow easy passage of all bullets, “but it can’t be oversize,” cautions John Krieger. “A little bullet wobble ruins accuracy.” As long throats keep a lid on pressure, Roy Weatherby used them to hike bullet speeds.

The uniformity of finished bores may be checked with an air gauge, a probe that moves through the barrel with air pressure “feeling out” variance down to 50 millionths of an inch! In addition, John Krieger lops an inch of barrel from the muzzle before crowning because “bore finishing can leave a flare.” The KCR has a recessed target crown to protect the bore lip and ensure perfectly square bullet exit.

The KCR’s Mark V action is a refined version of the mechanism Roy Weatherby engineer Fred Jennie developed to accommodate the .378 Weatherby cartridge after its 1953 introduction. To see how a current Mark V rifle comes about, I visited the Paso Robles assembly floor. The KCR had yet to emerge then, but the staff was boxing up rifles in the spanking-new 6.5-300 Magnum. Charitably, Ed Weatherby said: “You might as well build one.”

He’d have been foolish to turn me loose in that shop. Instead, a handful of skilled rifle builders guided me through 36 shop operations to bring a Mark V from 33 parts to completion. In the test tunnel, it drilled a 0.7-inch knot. “All Weatherby rifles must now meet a 1-MOA standard,” confirms Adam. “Rifles marked ‘Range Certified’ come with a proof target from Oehler’s Ballistic Imaging System, and load data developed by Weatherby for that rifle.”

As I’ve known John Krieger for years and used his barrels on other rifles, I requested a sample of the KCR right away. It comes in four Weatherby Magnum chamberings: .257, 6.5-300, .300 and .30-378. Noise and recoil have become less appealing with age, so I was pleased the crew shipped a .257. One of Roy’s favorite cartridges, it was also one of his first. In fact, its 1944 debut predated his rifle company! Factory-loaded ammo appeared in 1948. The .257 was on Norma’s list when it began supplying Weatherby ammo in 1951. Norma currently lists seven loads under Weatherby’s label, with five bullet weights.

Under The Hood

At 3,870 fps, the 80-grain TTSX bullet in the .257 Magnum is faster at launch than any other load for any Weatherby cartridge. Three 100-grain spitzers at 3,500-3,600 fps also qualify as hotrods. But to get ballistic coefficients above .400 and weights suitable for elk, and to better tap the .257’s case capacity, I turned to 110-grain AccuBonds at 3,460 fps, 115-grain ballistic tips at 3,400 fps and 120-grain partitions at 3,305 fps.

Roy Weatherby’s notes on the .257 during his African safari came to mind.

“The 87-grain bullet seems to have more killing power at 100 yards than does the 100-grain.” Still, his unvarnished reports later showed that light bullet at nearly 4,000 fps didn’t excel in all situations. Thus, it’s no longer loaded. I have limited field experience with this hot .25, but bullets in all weights are much better now. A deer I shot in Idaho at 325 yards dropped as if lightning-struck when my 100-grain Hornady pierced its ribs.

After the KCR arrived, I attached a Burris Veracity 2-10×42 scope in Talley mounts. This 30mm glass, with focus/parallax dial and mid-height target knobs, is long enough and heavy enough to dominate lightweight rifles, but it’s an ideal fit for the leggy, 8.5-pound KCR.

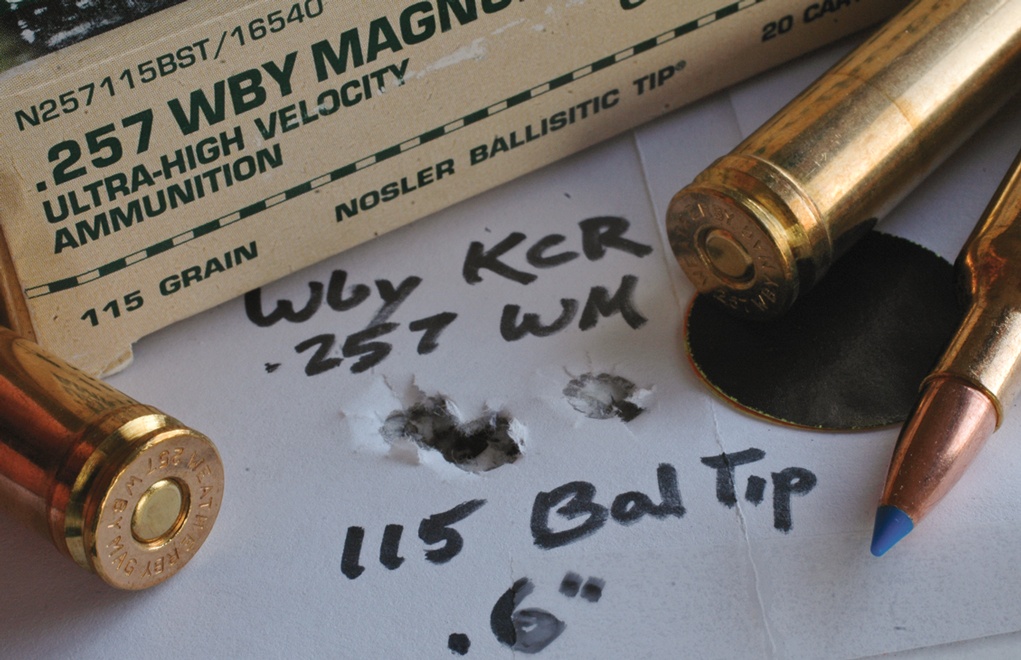

At the range, this rifle cycled smoothly and in all other ways behaved without fault. My Timney scale registered trigger weight at the specified 3.5 pounds, exactly. The big bolt knob was a delight. All groups stayed inside the 1-inch maximum, including five shots with the AccuBonds at 0.6 inch, the best three-shot group went to the ballistic tips. I’m still working with it, but 0.6 MOA is mighty fine accuracy. Also, successive bullets went to the same place even as their blazing speed hiked bore temperatures.

Yes, the KCR — one of three new Mark Vs in a field of 18 — is expensive. But in my view, it ranks among Weatherby’s best. Top chambering? I’m fond of the .300 Weatherby. On the other hand, this .257 is so civil in recoil that it’s hard to believe that the three loads I fired bring an average of more than 1,300 ft-lbs. to 500 yards, and the most accurate will keep all bullets inside the mouth of a coffee mug at that range!

Editor's Note: This article originally appeared in the June 2018 issue of Gun Digest the Magazine.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)