Solid bullets have become much more than a big ol’ hunk of lead.

What are the three classifications of modern solid bullets:

The evolution of the solid bullet as a hunting bullet has taken numerous twists over the centuries, tied to advancements in firearms and the switch from black to smokeless powder. The earliest projectiles were made of almost anything: rocks, wood and metal. But soon after the invention of firearms, arms makers realized that something of considerable density was required if the projectile was to retain velocity. Fortunately, lead is very dense, plentiful and cheap. And lead could be molded to fit a gun’s bore for better accuracy.

The first “solid bullets” were round balls, but accuracy with these spheres in the smoothbores of the day limited range. This changed with the invention of rifling. Some of the first rifled barrels had straight grooves, but it was discovered that spiral rifling imparted a spin to the bullet that greatly improved accuracy. Round balls and bore diameters got bigger in an attempt to increase lethality, but eventually, the round ball gave way to a solid, elongated cylinder, with a round or pointed nose.

Another development that helped accuracy was cast bullets with a hollow base. This was at first filled with tallow, but it was discovered that the fat wasn’t needed, and that the base of the soft lead bullet expanded to fit the rifling.

All such bullets were solids, but the transition from black to smokeless powder and the development of self-contained cartridge resulted in velocities far beyond the capabilities of bare lead. Eventually, bullets with jackets of some material were developed to protect the lead. The first jacketed bullets were paper-patched solids, but soon various metals encased lead cores.

It’s important to note that the first “bullets” were all solids, at first made of pure lead, or an alloy thereof. Today, solids are available in basically three distinctly different pillars of classification.

Solid Lead-Alloy Bullets

First are the long, heavy, solid lead-alloy bullets of early cartridge arms, still used in modern replicas of the big buffalo rifles.

Solid lead-alloy bullets are the mainstays of the blackpowder cartridge rifle shooter, and various alloys, lubricants and specialized loading techniques make the accuracy of such loads amazing. When the government was doing research on a new blackpowder service cartridge, they tested .40-, .42- and .45-caliber cartridges, with both bottle-necked and straight cases. Straight-walled case gave the best accuracy and the least pressure, and the .45 caliber gave the best results, especially at long range.

Thus, the .45-70 Government as adopted was loaded with 70 grains of black powder and a 400-grain solid lead bullet. However, it was found that the 70-grain powder charge produced too much recoil, so the charge was reduced to 55 grains with the same bullet (called, logically enough, the .45-55). The 500-grain lead bullet, so popular today in the .45-70 with target shooters, wasn’t loaded by the Army until about 1881. While modern-day hunters scoff at the “low-powered old .45-70,” consider this: A 500-grain lead bullet launched at about 1,100 fps will shoot through a bison, end to end. There are also reports of cavalrymen at the Custer battle knocking off Indians at over 600 yards with their .45-70 carbines.

Soild Non-Lead Bullets

Second are the non-lead solids for big game, some of which are especially designed to (a) penetrate and expand, or (b) penetrate and not expand at all.

The second tier of solid bullets is a relatively new development, spawned in part by the actions of brain-dead bureaucrats demanding no-lead bullets, and, ironically, the honest desire of companies trying to literally make a better bullet.

Randi and Connie Brooks purchased an almost defunct bullet outfit in 1974, and renamed it Barnes Bullets. The new company designed, perfected and introduced the Barnes X-Bullet in 1989. It was truly a solid composed of copper with a hollow tip that helped initiate expansion. But the smooth shank was unforgiving: In over- and under-sized bores, accuracy was a sometimes thing.

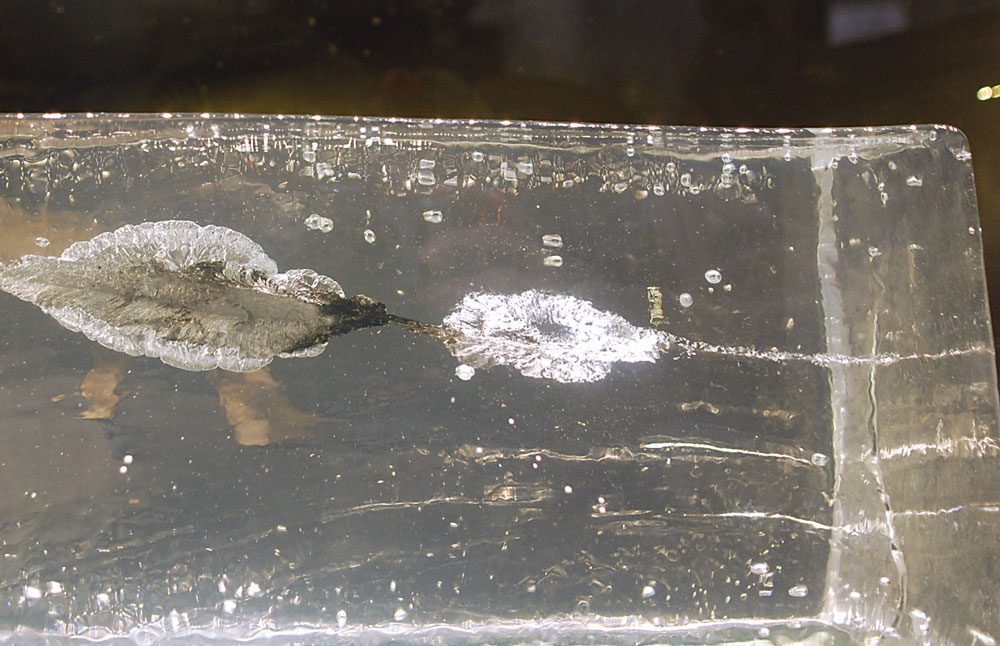

So the X-Bullet was modified by the addition of rings cut into the shank, and it was renamed the Triple Shock-X. While the TS-X is made of a homogeneous material, it’s technically a solid, but it always expands, penetrates and retains almost 100 percent of its weight. TS-X Bullets were soon followed by versions with a polymer tip.

In 2009, Hornady introduced a solid bullet they call the GMX: the Gilding Metal eXpanding. It’s made of 95 percent/5 percent (copper-zinc) gilding metal, sports Hornady’s signature red polymer tip and has a boat tail. The GMX gives deep penetration, reliable expansion and about 95 percent weight retention. It also has a crimping cannelure and what Hornady calls “pressure relieving grooves” in the shank.

In 2007, Nosler introduced the Nosler E-Tip Bullet (the “E” is for the “E2 Energy Expansion Cavity”). The E-Tip is also composed of a copper alloy with a signature green polymer tip. The big difference in the E-Tip is that its shank is smooth. The shanks of the first E-Tips were totally devoid of grooves, but in 2014, Nosler added a shallow crimping groove.

One of the new entries into the world of solid bullets is from Fort Scott Munitions (FSM). FSM took a radical approach to the design of the solid, monolithic hunting bullet, and has developed an extensive line of projectiles and factory loaded ammo.

Here’s their rationale: To reliably and quickly kill big game, a bullet has to disrupt a lot of vital tissue. Traditionally, this has been done with bullets that penetrate and expand. The poor performance of full-metal jacketed bullets in game is well documented, as military bullets with a full-metal jacket and a traditional lead core start tumbling after impact, and then fragment. These small fragments then rapidly loose speed and effectiveness.

FSM’s monolithic bullets are designed not to expand, but tumble upon impact in soft tissue, and produce penetration and tissue damage equal to, or exceeding, that of traditional expanding jacketed bullets. In bone, they just bore straight ahead. FSM calls their bullets “Solid Copper Spun” (SCS) or “Solid Brass Spun” (SBS). Another benefit of these bullets is that they are totally lead-free, and thus suitable for use in jurisdictions where bullets that contain lead are prohibited.

Non-Deforming Solid Bullets

The last category of solid bullets is the one of which most shooters think with we use the term “solid.” These bullets are not made of one material and have jackets, but rather are “solids” in the sense that they do not deform, no matter what they’re shot into.

Many years ago, Hornady developed a steel-jacketed solid that covered a traditional lead core. The steel was then covered with gilding metal jacket, like that used for conventional cup-and-core bullets. Today, that bullet design has evolved into the exemplary DGS (Dangerous Game Solid).

Non-expanding solids for dangerous game are also available from Barnes. Introduced in 2005, these are called banded solids, due to the four or five circumferential grooves in the shank for displaced metal. These “solids” are made of a copper/zinc alloy and are available from .338-caliber to the big British cartridges, including the 600 Nitro Express and the .50-caliber BMG.

Nosler Solid Dangerous Game bullets debuted in 2008 and are somewhat similar to the Barnes design, except that they have but one groove in the shank. I’m unaware of the exact composition of these bullets, but the lead-free alloy looks like pure Naval brass to me.

The Future Of Solid Bullets

Thus, the solid bullet lives on in original lead (or alloy) projectiles of early days, plus today’s new homogenous bullets — some of which are designed to expand, and some of which are not. In addition, there are new non-expanding “dangerous game” balls, made of various substances, or covered with tough jackets that protect the bullet’s core as well as the rifle’s bore, and engage the rifling. To be sure, we’ve not seen the last of innovation in the design of such bullets.

Editor's Note: This article originally appeared in the 2018 Shooter's Guide issue of Gun Digest the Magazine.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)