Bullets, powder, primers and cases … they aren't all the same, even when they're from the same lot. Understanding the issues surrounding reloading component variations is the first step to overcoming them.

Precision handloaded ammunition is all about consistency in dimension, weight and results. We take great care in the setup and maintenance of our gear (dies, scales and other tools can come out of adjustment) and strive to buy the best components we can afford.

However, we are at the mercy of those who produce the reloading components.

If Brand X bullets deliver the hair-splitting accuracy you’re after when fueled by a specific amount of Brand Y powder and Brand Z primers in Fedchesterton cases, we carefully record that recipe and replicate it each reloading session. But, should the X, Y or Z component change or become unavailable, the end result will invariably change as well.

Dealing With Variations

How can this be helped? What can we do to combat the inevitable (even if slight) reloading component variations?

Regarding the bullets, it’s going to be a decision to use them or not. Certain brands of bullets will definitely run to tighter tolerances than others, and weighing and/or measuring them will show the variations in the projectile. If the weight or dimensional variations don’t affect the accuracy of your load to the point at which you’re uncomfortable, then feel free to load away. A bit of experimentation will show you whether or not you should be concerned.

For example, there’s a particular 150-grain bonded-core, boat-tail bullet that performs very well in my .308 Winchester, and I took the time to weigh out the box of 100 projectiles. The lowest weight was 149.4 grains, and the highest weight was 150.7. I rounded the weights to the nearest ½ grain and ended up with three piles of bullets weighing 149½, 150 and 150½ grains.

This particular rifle gives sub-MOA accuracy with any bullet out of that box, but it gave under ½ MOA when the bullets were segregated. The point here is that if you want to wring the most accuracy out of your rig, bullets of a consistent weight (and, in theory, of consistent dimension) will definitely help you out.

Check Out The Gun Digest Reloading Data Center

Powder Variations

Powder can show variations from one lot to another as well, and that will change pressures, velocity and accuracy. Although the consistency of modern smokeless powder has improved greatly, there are still variations.

I recently had the opportunity to tour the Norma Ammunition factory in Amotfors, Sweden, and was able to examine how this company handles its African PH line of ammunition.

Interestingly, the entire line of African PH ammo is handloaded to stringent specifications, which is rare for “factory” ammunition, but I found the way Norma handles the variation in powder performance even more interesting. Each caliber is—quite obviously—loaded to a specific target velocity. But this becomes much more important when it comes to the ammunition for double rifles, for which the pair of barrels is regulated for a certain velocity.

Norma performs regular testing of its ammunition, adjusting the powder charge slightly to adjust for the variations in each lot of powder. You can do the same with your , depending on the testing environment you have, as well as the variations in environmental conditions, and you might end up developing data for different seasons.

Load Up On Reloading Info:

- The Flexible And Forgiving .30-06 Springfield

- The .45 Colt: A Wheelgun Classic

- .300 Win. Mag.: The Answer To Most Hunting Questions

- Tips For Reloading the .223 Remington

Aiming for Consistency

Chris Sells of Heym USA—a guy who knows a good deal about loading for double rifles—taught me how he uses a “winter” load and a “summer” load. My own double has two loads as well, with just a 1-grain variation needed to adjust the velocity.

I fully understand that the double rifle is a niche choice, but it illustrates how powder can fluctuate. In order to keep things as consistent as possible, Sells buys his powder in bulk. In a repeating rifle—most often equipped with an optic—we often assume the sighting system has come out of adjustment, when a change in the lot of powder is actually the culprit just as often.

As reloaders, we can’t easily test the burn rate of the powder we are loading nor compare the lot-to-lot variations, other than the results we see in velocity and accuracy. However, in an effort to keep things as consistent as possible, buying an 8-pound jug or a case of 1-pound canisters of the same lot will help keep things consistent in your gun.

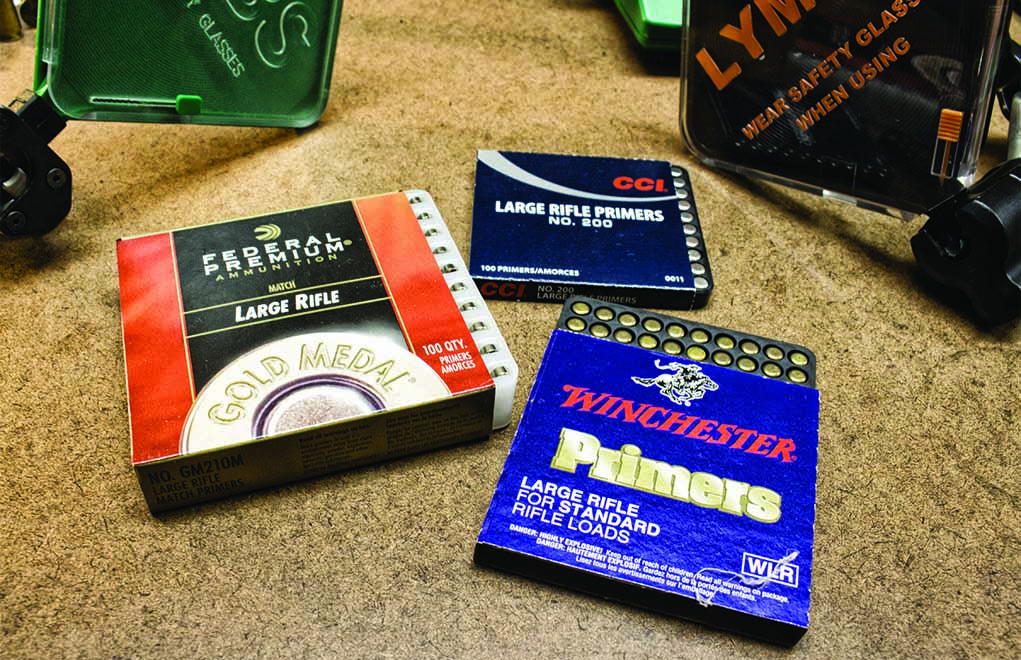

An overlooked reloading component, primers can also be a major factor in ammunition consistency. Should you find the need to switch primers from the brand and type with which you developed your load, it’s important that you restart the loading process at the bottom of the listed data and work up again. I’ve seen many loads—at or near the top of the chart—give dangerously high pressures when used with a primer change.

As with powder, I prefer to buy my primers in bulk. I use many different brands and types of primers for my own rifles; and, within certain cartridges, I use a number of different primers for different bullets. They aren’t interchangeable, however … at least not if I want to maintain the accuracy I’ve worked so hard to establish.

I find that if the proper amount of preparation is applied, a good handloader can make just about any brand of case work. Not all brands are created equal, and some brands are of better quality than others. Every reloader will have their particular favorite.

I’ll certainly agree that those brands of cases that are properly annealed will give the longest life, and it can be immediately obvious with just a visual inspection which brands take the most time and effort to produce the best product available.

I’ll always recommend using the best cases you can afford, but I’ve fueled entire safaris with once-fired brass given to me by a charitable soul. The only consistent thing about them was the marking on the headstamp.

Parting Shot On Reloading Components

In the grand scheme of things, if all our reloading components were absolutely consistent, our ammunition could still be compromised by our technique. Add in the variations of the components, and you have another source of inconsistency.

As with all things in the reloading/handloading world, we need to learn to combat these issues to mitigate the amount of error introduced to the ammunition. Understanding the issues is the first step to overcoming them.

Editor's Note: This article originally appeared in the January 2020 issue of Gun Digest the Magazine.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)