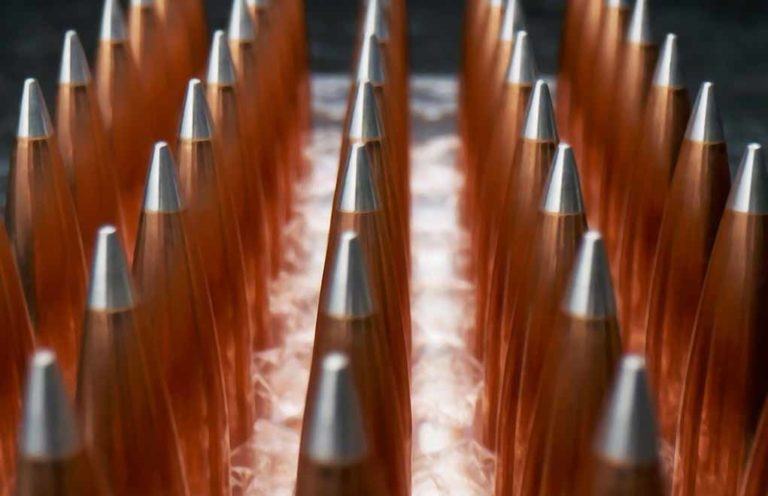

Aluminum tipped, the Hornady A-Tip line goes way beyond the average match bullet.

How Hornady A-Tip Bullets Enhance Long-Range Shooting:

- Longer aluminum tips enhancing stability.

- Reduces drag variability.

- Forgiving of twist rate, seating depth and muzzle velocity.

- Sequentially packaged to provide the most uniform batch.

The ‘A’ is for aluminum.

Since we’ve got that cleared up, the new Hornady A-Tip line of bullets gets pretty self-explanatory. At least, as to why the high ballistic coefficient projectiles sport unique tips. But it raises the question, why go to all the effort? As with anything shooting the answer is simple – accuracy.

Generally speaking, shooters had two styles of production match bullets at their disposal to date – open tip match and polymer tip. Little arguing the bullets have more than fit the bill, given the distances and consistency they’ve achieved over the years. Yet, each has their drawbacks, from manufacturing irregularities to melting (in the case of polymers) down range, and even being susceptible to dings when chambered. What that leads to are inconsistencies. At 1,000 yards and beyond that spells trouble.

Not so with aluminum, which is more resilient, easier to hold to tighter tolerances and offers more bullet-to-bullet uniformity. There’s also the added benefit that metal can be machined metal longer than polymer, thus increasing the bullet’s BC. Hence, the Hornady A-Tip.

Though, there’s a bit more going on with the bullets than improved material and ability to overcome wind resistance. Hornady has striven for the utmost consistency with the line and has gone to what some might call absurd lengths to achieve it. Aside from machining the tip specifically for the three calibers presently manufactured (6mm, 6.5mm and .308), the company said it minimizes human contact with the projectiles. That is until they reach you. Even then, the company includes a polishing rag to remove any blemishes you might leave.

Load Up On Reloading Info:

- The Flexible And Forgiving .30-06 Springfield

- The .45 Colt: A Wheelgun Classic

- .300 Win. Mag.: The Answer To Most Hunting Questions

- Tips For Reloading the .223 Remington

Furthermore, the bullets are sequentially boxed, every bullet comes from the same run. In turn, any variation in the machinery over time is minimized in the bullets you buy. In short, your batch should be nearly identical in geometry and weight. No more breaking out the scales to put each bullet in the balance, by Hornady’s telling. I’m betting reloaders still do – you can’t leave anything to chance.

Hornady dropped the hammer on the A-Tip, because it said it had found a way to cost-effectively machine the tips. But they’re not exactly cheap. A quick look at online reloading retailers, a box of 100 runs just shy of $80. Yet, if they find the same hole over and over as Hornady claims, A-Tips will prove priceless.

More from Hornady:

(Grand Island, Nebr.) — The Hornady® Ballistic Development Group (BDG), a specialty research and design group at Hornady Manufacturing, has developed a new line of match bullets for the ultimate in precision and long-range shooting.

By drawing on years of research and experience with existing products like the ELD-X® and ELD® Match bullet lines, state-of-the-art equipment including Doppler radar, high-speed camera systems, plus investment in advanced manufacturing machinery, processes and quality control measures, the BDG has developed the A-Tip™ line of match projectiles.

By drawing on years of research and experience with existing products like the ELD-X® and ELD® Match bullet lines, state-of-the-art equipment including Doppler radar, high-speed camera systems, plus investment in advanced manufacturing machinery, processes and quality control measures, the BDG has developed the A-Tip™ line of match projectiles.

The most striking visual feature of the A-Tip™ bullet is its long, uniform, precision-machined aluminum tip.

“We wanted to incorporate aluminum tips in a full line of match bullets for years because we can make longer tips than we can with polymer materials,” said Joe Thielen, Assistant Director of Engineering. “This longer tip is a key component that helps move the center of gravity of the bullet rearward, thus enhancing in-flight stability and reducing dispersion. The problem has always been the cost to produce a tip like this, but we’ve developed a cost-effective process for manufacturing these aluminum tips while staying affordable for serious match shooters.”

The longer aluminum tips are machined to be caliber-specific, and when coupled with highly refined AMP® bullet jackets, aggressive profiles and optimized boattails, the result is enhanced drag efficiency (high BC) across the board. Each bullet design is carefully crafted for minimal drag variability for the utmost in shot-to-shot consistent downrange accuracy.

The materials, design and manufacturing techniques combine for the most consistent and accurate match bullets available.

“We designed the A-Tip™ projectiles with accuracy and precision first and foremost,” Thielen added. “Many low-drag bullets on the market today have very aggressive secant ogives, which look great on paper and yield high BCs, but usually these types of projectiles are very finicky when it comes to accuracy or performance in different chambers, standard twist rates, seating depths and barrels.”

In addition to developing projectiles that will shoot well in a variety of chambers, the BDG also designed the A-Tip™ bullets with the right balance between the center of gravity of the projectile versus center of pressure to minimize in-flight drag variability.

The A-Tip™ bullets are also packaged sequentially right off the bullet press without being batch handled or tumbled, ensuring that each bullet in the box is a clone of the bullet before it — and after it.

A-Tip™ bullets will be available in 100-count boxes, and retailers will also sell sleeves of five sequential 100-count boxes packaged together, as well as a case pack of two 500-count sleeves for a total of 1,000 sequentially packed bullets. Since the bullets will not be touched or tumbled, there will be some slight oil residue, so a bullet polishing bag will be included with each 100-count box for the hand loader to use in preparing bullets for loading.

This change in manufacturing and packaging is a welcome and unique challenge for a company built on large-scale manufacturing.

“We are frequently viewed as a very large bullet manufacturer, which in many ways we are, but the Ballistic Development Group runs like its own small ‘skunkworks’ division that allows us to offer the small-batch craftsmanship normally only offered by a boutique bullet maker,” said Jason Hornady, Vice President. “We’re shooters ourselves, and we also listen to what shooters want, and we are excited to be able to offer competitive and hard-core shooting enthusiasts projectiles that are undoubtedly the new standard bearer of precision and performance.”

Initial offerings of the A-Tip™ bullet include the following listings with Doppler radar measured G1 and G7 BCs:

·6mm 110 grain G1: .604 G7: .304

·6.5mm 135 grain G1: .637 G7: .321

·6.5mm 153 grain G1: .704 G7: .355

·30 caliber 230 grain G1: .823 G7: .414

·30 caliber 250 grain G1: .878 G7: .442

For more information on Hornady A-Tip bullets, please visit www.hornady.com.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)