LATE ONE NIGHT – we always work into the small hours – your editor called me, suggesting I dig through the files for some handloading hints or techniques, for solutions to problems that readers from all over the country have described to us. The odds and ends that follow are the careful gleanings of a couple evenings I spent going over the past two years' correspondence and columns.

If you find yourself without something to ream out military-primer crimp, try this: pick up a low-cost 45” or 60” countersink at the hardware store; then grind its point back until it enters the primer pocket deeply enough to cut away the crimp. The end then acts as a stop to prevent cutting too deep. Used by hand it will do a good job, leaving a clean bevel at the pocket mouth to facilitate entry of a new primer.

It can also be used under power (as can a Lyman or other primer pocket reamer) in a variable-speed drill press or electric hand drill. Run at lowest speed and press cases over the cutter by hand. You might find this handier than other methods.

Primers

Rifle primers in handguns? It isn't a good practice for several reasons: rifle primers require a heavier firing pin blow for proper ignition; the greater amount of priming compound may increase pressures (not necessarily dangerously); and handgun-case primer pockets aren't always deep enough for rifle primers.

Big, heavy frame revolvers (S&W N, Colt New Service, Colt & Ruger SA, etc.) have heavy hammers, strong mainsprings, and long hammer travel. In my experience they will reliably ignite rifle primers. During wartime periods of component shortages I used thousands of rifle primers in such handguns without any ignition problems at all.

(Left) This long-tube Bonanza funnel will serve to get more powder in the case – greater falls of granules help compaction.

On the other hand, I've yet to encounter an autoloader, even the 45 Government Model, which would ignite rifle primers reliably. As for small- or medium-frame revolvers, the latter will sometimes do well with rifle caps, the former hardly ever.

Recognize these limitations and be guided accordingly, should you be tempted to use rifle primers in handgun loads simply because they are available or cheap.

Note well! Never take primers out of their compartmented containers until ready for use; never store loose primers in bulk, and never agitate or shock loose primers. To do any of these things can set up a dangerous condition, one which might produce an explosion.

In spite of Boxer primers being far more widely used today than ever before, someone will occasionally find it necessary to shoot – and eventually reload – Berdan-primed cases. With many of the older British and metric calibers now or soon-to-be discontinued, we have no choice but to hoard such ammo and cases as are available against future needs. Such ammunition is Berdan-primed, and no more will be produced. So long as you save the cases in good condition, you can generally find powder and bullets suitable for reloading them.

Primers, though, could be a problem in the future. The more common Berdan sizes suitable for fairly modern metric cases will likely be available for a long time. The principal sizes, .177-inch, .217-inch and slight variations thereof, are available. The 250-inch and .254-inch can still be had, but are getting scarcer. These basic metric sizes can be obtained through dealers from Godfrey Reloading Service, Box 12, Alton, Illinois 62002, and Stoeger Arms, 55 Ruta Court, South Hackensack, New Jersey 07606, in modern non-corrosive, non-mercuric form.

Berdan primers for the various big-bore British cartridges are of different sizes and harder to obtain. Further, they aren't likely to be available much longer. Some sizes are still available from Oregon Ammunition Service, Box 19341, Portland, Oregon 97291, but not in especially great quantities.

The solution to being able to shoot those odd calibers in the future is to lay in a supply of the primers you need now. Don't get greedy, though – you won't really shoot that 10.75x 68mm or that 475 No. 2 Nitro more than a few hundred times at most over the rest of your powder-burning days. So don't try to corner the Berdan primer market – a thousand will surely do in each of the sizes you'll need.

It may be quite a while, though, before you'll use all those primers. How to keep them from deteriorating so that a decade or so from now they'll perform properly? First, make sure the original containers are sealed and in good condition, then separate into batches of two or three hundred each (British are packed 250 per sealed tin). Obtain small containers that can be sealed air-tight and seal up each small batch separately, putting a few dessicant pellets in with each. Label and date, then store in a safe dry place where temperatures won't go above about 80 degrees. Don't mess with them and 10 years or more from now they'll still be perfect.

As for containers, I'm partial to half-pint glass Mason jars with gasketed, screw-on lids. I spray them with black paint after sealing to keep out light which will fade primer carton labels – not really necessary, but convenient.

Flash Holes

As long as these are located reasonably near the center of the pocket, there'll be no measurable effect on accuracy. Hole size also has very little effect except when very wide variations exist within the same lot. However, size can be controlled, location can't. In any given lot of cases, simply check flash holes with a set of small-size twist drills. Then pick the drill size matching the largest hole, and use it to open all others to match.

A variation of this is to use a set of taper-pin reamers. Fit a stop on the reamer that enters the largest hole about half its length, then run it into all others. The stop will limit reamer travel and insure uniform hole diameter.

Non-Corrosive vs. Corrosive Primers

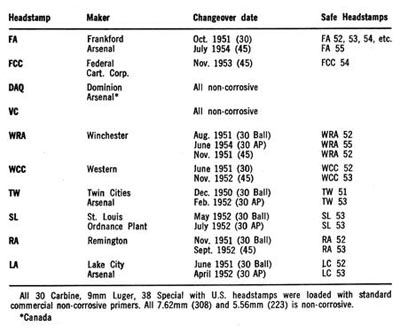

This question comes up frequently – how do you tell which military ammunition is loaded with corrosive or non-corrosive primers? The best answer available, insofar as domestic ammunition is concerned, is found in the chart reprinted here from Modern Handloading, available from Winchester Press: Foreign military surplus ammunition is another problem entirely, and accurate information is almost impossible to obtain. During WW II and immediately following, only very small amounts of foreign military ammunition were assembled with non-corrosive primers. The most notable exceptions are the Boxer-primed Canadian production of 9mm Para-bellum and 30-06. Beyond that the only safe assumption is that any foreign military surplus manufactured before the late 1950s and early 1960s is probably assembled with corrosive chlorate primers and clean your guns accordingly.

Powder/Cases

We often hear complaints about an inability to get certain recommended powder charges into the case in question. For example, the Speer Reloading Manual No. 8 lists a charge of 59 grains of H4831 powder with a 180-gr. bullet. Shooters without a great deal of experience in this particular area choose this load, set up the powder measure, check it out, and then go into a sizzling sweat when they discover that as dropped from the measure, that charge overflows the case – you just can't get that much loose 4831 into the case. They immediately suspect that load of being erroneous – and naturally, that perhaps other data in the manual might also be incorrect. Now they're afraid to use any of the dope in their particular manual – and it may be the only one at hand.

All this is understandable, but just a wee bit more knowledge would save the day. Like any other granular material, propellant powders can be made to occupy a lot less space than they do when simply dumped loosely into a container. You think nothing of jarring or vibrating a container of other physically similar materials to settle the contents into less space, so why not powder?

The old-timers whipped this problem with black powder by using a long drop tube or loading tube, which caused the powder to fall as much as three feet before it entered the case, thus compacting itself. If no great amount of compaction was required to get the charge in the case, they simply compressed the powder during bullet seating. Both methods will work today, but the use of a long loading tube is a considerable inconvenience and compressing the charge with the bullet can result in the fracture of a good many powder granules, causing ignition and burning rates to vary. By far the best method I've found is to simply put the case fully up into the conical mouth of the measure drop tube, throw the charge, then rap on the head of the case with a length of brass rod to settle the powder. Depending on which powder is involved, this method settles the charge as much as 10-20% of its normal as-dropped bulk.

Autoloaders and Loads

Next time you have extraction or ejection difficulties with handloads in any auto shotgun, check the gun closely before blaming the ammunition. That the gun works OK with factory ammo doesn't mean it's perfect.

First, thoroughly clean the gas cylinder and piston (if present), all recoiling parts, and especially the chamber. Examine all moving parts carefully for burrs, deformation, or excessive wear that produces extra friction. Examine the chamber carefully for evidence of rust pitting, scratches and gouges, burrs, reamer marks, or hard-caked fouling patches. Make certain the gas port isn't partially clogged.

Autoloaders such as this FN M1949 ABL can be finicky about handloads and sometimes need extra care.

The chamber is especially important. In some guns functioning may be OK with factory loads, then erratic when same cases are handloaded to the same performance. Handloaded cases may cling just a little more to chamber walls – enough to slow down extraction and cause a bit of trouble.

Getting the chamber absolutely clean and then polishing away any roughness should cure the problem. But be sure you polish only; don't grind the chamber oversize. It only needs smoothing, not enlargement.

As a last resort – when you've a batch of handloads that just don't quite give full cycling – the situation can be salvaged by lubricating the cases. Hang me in effigy if you like for such a heretical suggestion, but it does often allow proper functioning without apparent ill effects. Just a trace of lube, though, or it will build up in the chamber. I've had good results with wiping cases lightly with a cloth into which has been rubbed a good paste wax. Other times I've rubbed just a trace of resizing lube on with my fingers.

As for handguns, it has long been the practice of many first-class competitive shooters to literally drench lightly-loaded cartridges with oil to insure reliable feeding. Many a 45 auto that won't work at all well with 3.2 or 3.3 grains of Bullseye in dry cases, will perform flawlessly when the same cartridges are well oiled. The usual procedure is to just squirt oil into the magazine after it is charged.

In the final analysis ammunition lubrication can be safe and worthwhile. Generally speaking, it becomes dangerous only when very high chamber pressures are combined with excessive amounts of lube.

Defense Loads

Much has been said about the use of lead, hollow-base wadcutter bullets in 38 Special for defense purposes. The 146/148-gr. full wadcutter bullet loaded by all ammunition manufacturers is a pretty fair manstopper in its own right, if its velocity is stepped up a bit. The current factory-load velocity of about 770 fps (in a 6” test barrel) dribbles off badly in barrels under 4” long, so it doesn't have much smash – but even so, it's more effective than the smaller revolver cartridges and most auto-pistol calibers under 9mm.

This current loading is labeled “mid-range,” thus its mild disposition. There was once a “full-charge” wadcutter load, now discontinued, with a good deal more authority, delivering the same bullet at 870 fps. On paper it was nearly as good as the standard 158-gr. round nose load, but in practice it was far superior.

That flat-ended, soft-lead slug penetrated far less, thus transferee! more energy to the target; it created a larger wound channel and more secondary projectiles; it was generally bad news to any animated target.

If you want to use the HB wadcutter in your defensive handloads, by all means copy the full-charge load of yesteryear. Bullseye powder does the job well, with 3.5 grains giving about 880 fps; 4.5 grains of Unique will do about the same.

Going higher, 4.4 grains of Bulls-eye or 5.6 grains of Unique will churn up just over 1000 fps for particularly deadly results. But at this MV level accuracy may go to pot unless bullets are cast quite hard. The walls of the bullet base, around the cavity, are thin and weak, and they may be badly deformed by gas pressure as the bullet leaves the muzzle.

Of course, all commercially available HB wadcutters are made from very soft lead, so they don't take kindly to being souped-up much past the old full-charge velocity.

There's also the practice of loading soft HB wadcutters inverted to produce what looks like a massive hollow point. Even at low velocities this will produce considerable expansion in tissue; at higher velocities it will fragment, throwing off pieces which add to the destruction it causes.

While the modest load of 3.5/Bulls-eye and the inverted HB is highly favored by some; others complain about its accuracy. The problem arises in the degree of accuracy required. Generally, it's recommended as a defense load in 2” guns at across-counter ranges where minimum blast and recoil are desired.

Micrometers

No serious hand-loader can consider himself properly equipped if he doesn't own a first-class zero-to-one-inch micrometer and a four-inch or larger capacity vernier caliper of comparable quality.

No serious hand-loader can consider himself properly equipped if he doesn't own a first-class zero-to-one-inch micrometer and a four-inch or larger capacity vernier caliper of comparable quality.

(Left) To insure higher accuracy and safety, all cases should be checked frequently, particularly those for rimless autoloaders. The 9mm Luger is shown. Every handloader should own good measuring instruments – a micrometer first, a 4” or 6” caliper like this as well.

They aren't exactly cheap, but the assurance that accurate measurements give you, and the hazards they help you avoid, are worth many times the cost. If you live in a highly industrialized area, you'll find excellent buys in good used tools in hock shops and second-hand stores. If not, any good hardware or tool store can fix you up, or you can use one of the many mailorder tool catalogs.

First-class domestic brands will cost in the $25-40 range, but adequate less expensive models are available. Some importers offer excellent imports for substantially less – but don't get the idea one of those “Super Precision” $2.98 mikes advertised in the pulp magazines will serve your purpose. It won't, and it might be so far off as to lead you into trouble.

A measuring tool is a precision instrument. If it doesn't look like it's made with precision, it likely isn't. Free but firm movement without backlash, smoothly finished parts, neat and mar-free assembly, clear and easily-read scales and graduations indicate good quality. If they aren't present, look elsewhere. A good mike or vernier will last all your life if properly used and cared for, so don't try to save fifty cents a year from now on by buying junk.

Case Annealing

The best method for annealing case necks is immersion in molten lead. It produces the most consistent case-to-case results, and it's simple and easy to do.

Fire up your electric bullet-casting furnace and generate a pot of molten lead; turn the heat as low as possible and still keep the lead completely fluid; skim off the dross, but do not flux the mixture.

Fire up your electric bullet-casting furnace and generate a pot of molten lead; turn the heat as low as possible and still keep the lead completely fluid; skim off the dross, but do not flux the mixture.

(Right) Best way to anneal cases is in molten lead, using a thermostatically-controlled electric furnace.

Pick up a case – either in fingers or pliers or some secure holding device – and dip case neck/shoulder area in light oil or finely powdered graphite. Give it a quick flip to throw off the excess, then immerse neck and shoulder vertically into the molten lead. Leave it there four or five seconds – thick brass may require a bit longer. Then draw out the case, give it a quick flip to throw off any clinging lead, and quench by dropping it into a bucket of cold water.

That completes the job, and it can be done just as quickly as you can pick up and dunk cases – even faster if you want to make a holding fixture that takes several cases. I've used perforated plates or strap hinges drilled to accept as many as 10 or 12 cases for simultaneous dunking. In fact, I once used a battered old serving fork whose tines would hold a half-dozen 30-06 cases by their extractor grooves.

Experiment with the time of immersion. Keep it as short as possible to still produce the degree of softness required, but don't overdo it and get necks so soft they crumple. Just enough to produce a bluish-brown surface color on the brass is about right. If you're worried about overdoing it, hold cases between thumb and forefinger. That way, you'll feel the head getting hot and pull and quench the case before your fingers get burned. It's a fail-safe system, but warm on the hands.

Dirty Shotshells

Ever wind up with a batch of really dirty fired shot-shells? If they are one-piece plastic like the Winchester AA, just wash 'em. Dump them into mama's automatic washer with any good detergent, set water temperature to cold or warm (if the latter, check first to make sure it doesn't get hot enough to soften or warp cases), set for the shortest cycle available, and switch it on. It's a good idea to place these in an old pillow case or mesh bag to make sure the inside of the washer drum doesn't get chipped, and this also makes handling them easier. Cases will come out clean as a whistle, though the inked-on markings will probably be removed.

To dry quickly, tumble in mama's dryer, with heat turned off or at least set as low as possible. The dryer will also serve to dry out paper or built-up plastic cases you might pick up on the range after a shower or heavy dew. Just make sure you don't run it too hot. The “nylon” setting usually works fine, without damage to cases.

Waxing Shotshells

If you're having trouble with hard shotshell resizing, first check the die. It may have some annular reamer marks or other roughness (maybe from rust you allowed to accumulate) causing most of the trouble. If polishing the die doesn't cure the problem, try a little wax to lubricate both die and cases. A trace of beeswax rubbed on a few cases now and then may do the job. If not, give all cases a shot of aerosol wax. Make sure this is a hard wax, not just an oily furniture polish. In a few minutes the volatile spray vehicle will evaporate, leaving just enough wax on the cases so they'll run smoothly through the die.

Revolver Case Extraction

How often have you been told that so long as a revolver load extracted easily, it didn't produce excessive pressures? Don't believe that. We've seen 357 Magnum cases fired at 55-60,000 psi literally fall out of a test barrel of their own weight. On the other hand, I've seen cases fired in a new revolver that required being driven out of the chambers after firing at a conservative 15-20,000 psi.

Chamber finish and case hardness gradient are what really control extraction effort, far more than chamber pressure. Take a revolver with smooth, slippery chambers (like S&W used to burnish them) and keep running pressures up – you'll blow the gun before extraction effort becomes excessive. On the other hand, take a recently-made gun of a make and model with all-too-common rough chambers, and even light factory loads may hang cases up solidly in chambers. I've seen lots of new guns the past few years that required polishing of the chambers before cases could be gotten out without the aid of a mallet or boot heel.

Don't take easy extraction as an indicator of safe pressures; instead, stick with known safe loads, and you're a lot less likely to wreck a good gun or your shooting hand.

Cartridge Corrosion

If you carry handgun loads in a typical looped leather cartridge belt, you'll eventually encounter corrosion problems. Brass cases will invariably develop greenish verdigris from contact with residual acids or moisture in the leather. The only way to prevent this with naked brass is to keep the leather as dry as possible and to remove and wipe the cartridges clean daily. Some police officers, not particularly gun-wise, coat their belted cartridges with clear lacquer or varnish. This will hold off corrosion, but unless very carefully done, it can cause chambering difficulties – especially with handloads whose cases aren't resized quite down to original dimensions. The lacquer may be thick enough to prevent chambering, especially if it runs or drips. A thin, well-buffed coat of hard paste wax will protect from corrosion for a while, but requires occasional renewal.

Your best bet is unscratched, unmarred, nickeled cases. The nickel must be unbroken, not scratched by resizing, so new cases are best for loads to be belt-carried for a long time.

Bullets will also corrode from contact with leather, whether lead or jacketed. Frequent wiping will do the trick, and so will a wax coating. However, lacquer can be safely used on bullets if not allowed to lap over onto the case. Dipping is okay if the lacquer is quite thin and the cartridge is hung point down by its rim to drain dry.

By far the worst method of avoiding or removing cartridge corrosion is buffing. Many a cop with a blitz cloth shines his belt ammunition by hand. That's OK because no metal is removed. But if this is tried on a powered buffing or polishing wheel, half the vital wall thickness can disappear in a flash. If the same rounds get another treatment later, they may be paper-thin, and rupture when fired. The rupture won't hurt the shooter, but if he's in the middle of a shooting encounter when it happens, the consequences might well be fatal.

7.62x39mm Cartridges

We continue to get many queries for a source of ammunition and/or components for the Soviet 7.62x39mm M-43 service cartridge for use in SKS carbines and its various copies. At least we hope they're for use in the semi-automatic SKS, for all the other guns chambered for that cartridge are full-automatic and thus prohibited by Federal law.

You won't find this ammunition in the average gunshop, but some surplus vendors occasionally have a supply of military loads. They are Berdan primed, but usually non-corrosive, and of good quality. What I've shot has been quite accurate in a Sako Vixen sporter.

Boxer-primed ammunition is, for all practical purposes, non-existent – though many millions of rounds have been loaded at the Lake City ammunition plant for the U.S. government. While you just might run across some of this loaded ammo, I'd recommend extreme caution. NONE has been legally released, and any you might encounter is most certainly “liberated” (for which read stolen) and possession thereof is frowned upon.

Boxer-primed ammunition is, for all practical purposes, non-existent – though many millions of rounds have been loaded at the Lake City ammunition plant for the U.S. government. While you just might run across some of this loaded ammo, I'd recommend extreme caution. NONE has been legally released, and any you might encounter is most certainly “liberated” (for which read stolen) and possession thereof is frowned upon.

(Right) These three 7.62x 39mm loads for Soviet SKS rifle are assembled in cases reformed from 6.5x 54mm Mannlicher-Schonauer brass.

The only other source of ready-made Boxer-primed cartridges I know is George Spence, Steele, Missouri. George custom-loads it, forming the cases from C.I.L. 6.5?54mm Mannlicher-Schoenauer primed cases he seems to have in plenty. He can also supply, at less cost, Berdan-primed loads made from reworked Italian 7.35mm ammunition of WW II vintage. Corrosive-primed, of course, but if you are too lazy to clean your guns, you deserve no better.

As a last resort for your own loading, use Norma unprimed cases in 6.5x54mm M-S or 6.5mm Carcano caliber and a set of 7.62x39mm forming dies, obtainable from RCBS, Inc., Box 1919, Oroville, California 95965. After resizing, trimming, neck-reaming, base-swaging, and annealing, you'll have excellent Boxer-primed cases which will serve for many, many reloadings if given proper care.

Though Russky and Chicom 7.62mm barrels usually run about .310” groove diameter, I've had fine results with standard .308” diameter 30-cal. bullets. Best were the 125/130-gr. weights, with fairly sharp points, ahead of IMR 4227 powder. Start at about 22 grains and work up until the gun in question gives reliable semi-auto functioning, then stop. This isn't a magnum, and even a smidgin more powder past the optimum level raises pressures sharply.

Black Powder

Having trouble getting enough black powder? Maybe it isn't as bad as it looks. The “User-Limited” purchase permit allows buying more than the picayunish 5 pounds normally allowed by Federal law, and also permits you to buy outside your state of residence.

In effect, a “User-Limited” permit enables the purchase of enough black powder at one time to make the often-necessary long drive pay off. A buying trip not worthwhile for 5 pounds isn't so bad if you can pick up 50 pounds, or if you can get together with several friends and send one man after enough powder for the whole lot.

Ask your local ATFD office for form #4707, execute it properly, then turn it in with the prescribed $2 fee. Eventually – there may be some delay – you'll receive a one-time purchase permit (Form #4709) which must be presented when and where your purchase is to be made. When making the purchase you'll also be required to execute a purchase record and to properly identify yourself.

Form #4709 is strictly a one-shot deal, and it's made out for a specific amount of powder. You can't buy more than the permit specifies – and if for some reason you buy less, you can't go back later and try to pick up the balance. Every individual purchase must be made under a new permit.

In some instances it might not be all that simple, depending upon your state and local laws and the state and local laws in force where you want to do the buying. Federal regulations specify that the permit will not be honored if the purchase or the transportation of the black powder will be in violation of state and local laws in the areas concerned.

Short Pistol Cases

A fellow dropped in the other day with his pet auto pistol and three or four boxes of cases fired in it – and with a problem. For years he had loaded straight rimless auto-pistol cases without any concern for case length. He knew that any case which had been fired successfully in that gun couldn't be too long – and he'd also felt that factory cases weren't likely to be too short.

He was a little shocked when he – for some reason – measured a few cases and found them much shorter than he'd expected. This prompted him to check quite a few cases – and none of them were long enough to headspace solidly on the chamber shoulder!

His first question was why the cases were generally a good bit shorter than published length. Well, there is no industry-standard minimum length for such cases, though maximum length is specified in SAAMI minimum-chamber/maximum-case drawings. Individual manufacturers set their own minimums compatible with tooling and production methods. So, since auto pistols are unusually tolerant of short cases and excess head-space conditions, tolerances are set rather loosely.

How loose? That information isn't released by the manufacturers, but a fair idea can be obtained by measuring a handful of cases from every make and lot you can find in one caliber. I once did this when a good many lots of commercial 45 ACP ammunition were handy. In one make alone I found a spread of.040” between longest and shortest cases. Other makes and lots showed a bit less spread, but still more than one might expect.

This doesn't mean that the cases or the makers are bad. As already mentioned, auto pistols are quite tolerant in this respect. Most autos have virtually unlimited firing pin protrusion, so will ignite a primer, even if the cartridge be rammed 1/16” deeper than normal in the chamber. So long as primers are ignited properly, the cartridges will function normally.

When it comes to producing maximum accuracy, though, those short cases can cause trouble. Uneven lengths will cause variations in ignition – which in turn produce greater velocity variations and a poorer degree of accuracy. The difference may not be much, even in a first-class target gun. But a half-inch in .50-yard group size can cost you a match just as easily as if it were a furlong.

To avoid such fuss and feathers, sort your once-fired cases by length. While a set of case gauges made up in .005” or .010” steps would be handy, I use a low-cost vernier caliper. Set aside for match use those cases no more than .010” shorter than breech-face/chamber-shoulder distance of the gun. The rest can be lumped together for general use, but you might want to split them into two batches, one for service use and the other for plinking where accuracy requirements are least stringent of all.

Minie Balls

Maybe you've acquired a muzzle-loading rifle of some sort (probably a 58) and want to use minie bullets in it. That presents no problem if your bore is of standard diameter. Lately, though, I've seen a few 58s with undersize bores – and standard minies are too large for easy loading. Of course, you can buy a new .575” or undersize mould, but that's expensive.

Maybe you've acquired a muzzle-loading rifle of some sort (probably a 58) and want to use minie bullets in it. That presents no problem if your bore is of standard diameter. Lately, though, I've seen a few 58s with undersize bores – and standard minies are too large for easy loading. Of course, you can buy a new .575” or undersize mould, but that's expensive.

(Left) Minie bullets – and some others – can be rolled to size if overlarge for your barrel. See text for details.

Try this instead. Take the standard too-tight minie bullets (unlubricated) and lay them on a smooth, hard surface. Steel plate is best, but smooth hardwood, glass, formica, rnasonite, etc., is O.K. Lay a strip of hardwood or steel over the bullet(s), bear down equally with both hands, and roll it on them a few turns. Experiment with pressure and don't overdo it. You'll find you can reduce bullet diameter a small amount quickly and easily. With a little care, you can reduce them quite uniformly.

Greasy Cases

When your hand-loads finish up a bit greasy – whether from bullet lube, sizing lube, or greasy hands and dies – it's best to clean and dry them before use, or before boxing and storage.

A power-driven tumbler is great for this, but if you don't have or can't afford one, you don't have to wipe off individual cartridges slowly and tediously. Just dig out a large, thick-napped bath or beach towel and sprinkle it lightly with lighter fluid or some similar grease-cutting solvent that evaporates quickly. Dump a couple hundred 38 Specials – or whatever it will hold conveniently – fold the towel over lengthwise, grasp it by both ends, and rapidly shuffle the loose rounds from end to end for a couple of minutes. The long nap and solvent will clean the cartridges, leaving them dry and bright. No more messy handling, and no oil-produced misfires.

When seating lubed lead bullets, especially if you're loading lots of 'em, lubricant often accumulates in the hollow of the seating screw, gets packed there tightly, and progressively forces bullets deeper into the cases. That causes wide velocity variations and consequent vertical stringing on the target.

When seating lubed lead bullets, especially if you're loading lots of 'em, lubricant often accumulates in the hollow of the seating screw, gets packed there tightly, and progressively forces bullets deeper into the cases. That causes wide velocity variations and consequent vertical stringing on the target.

Some dies are vented through the seating screw to allow excess lube to escape. That works part of the time, but the necessarily tiny vent is easily clogged and hard to clean.

(Left) 45 ACP load at left is shown with bullet seated correctly. The case at right has had the bullet driven too deeply by grease and dirt compacted in seating die.

Lube-free bullet noses will help a lot, even though some grease will occasionally be forced up along the bullet by the case mouth. The only sure solution is to swab out the die and the punch cavity now and then with a solvent-wet wad of cotton on a stick. If bullets are clean-nosed, doing this every hundred rounds or so will insure uniform seating depth and clean loaded cartridges.

Straight Cases

When loading such old long straight cases as the 45-70 and 45-90 for maximum performance in modern guns, the powder charge usually fills the case pretty well.

Most of today's handloaders hold the charge to the rear of the case with a loose ball of toilet tissue, kapok fluff, Dacron or some other light material. They all work, but none actually secures the powder's position quite as well as what the factories used in years gone by.

In straight cases an ultra-light ball of fluff will shift inside the case under the weight of the powder through handling and recoil impacts. When that happens, you aren't much better off than without it.

A tight-fitting card wad will grip the case walls better and will not shift nearly so easily. Hard, stiff, smooth cardboard at least 1/32-inch thick is best, and the wad must be large enough to fit quite tightly. It is tight enough when the edges are forced up slightly as it is rammed solidly onto the powder charge with the largest dowel the case will accept. Start the wad squarely by thumbing it into the case mouth, then seating it with a single smooth thrust of the dowel. Check afterward to make certain the wad hasn't scooped up part of the powder charge.

A dry wad will normally do the trick, but dipping it first into melted beeswax may improve accuracy, and will sometimes help with any leading problem that occurs. Adding a 1/16-inch wax or grease wad directly under the bullet may also help. Just make up a sheet of lube or wax, then thumb it over the case mouth, and seat the bullet directly over the resulting wad.

Editor’s Note: This article originally appeared in the 1976 Edition of Gun Digest Annual Book. Click here to learn more about joining the most extensive online repository of gun articles – over 65 years of Gun Digest books – found only at Gun Digest Research.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)