HOW CLOSE TO the rifling should the ogive of the bullet be for the best possible accuracy? This is open to debate, but we can agree that distance should be consistent, once we find the sweet spot, for shot-to-shot accuracy.

First off, you all should know that the ogive is, simply put, the spot where the bullet begins to curve to a point.

Using my Remington 700 .308 rifle the OAL (Over All Length) recommended in the loading books gave good accuracy. That accuracy improved as I moved the bullet closer to the rifling. This became apparent when I was fire-forming some new brass and I set the bullet right up to the rifling so the brass would form as concentric as possible. These fire-forming loads gave improved groups. With a little experimentation I found that setting my bullet back about .005 of an inch was the best for the rifle and load I was using. But how does a handloader best achieve the proper setback consistently once the measurement is established?

The OAL suggested in the reloading manuals will fit in every factory rifle out there. Moving the bullet forward for accuracy might jeopardize the ability to load rounds into the magazine. Thus you limited in your OAL to the size of the magazine. If accuracy is more important than quick follow-up shots you can get the bullet closer to the rifling, but you may end up with a single-shot rifle. This is one thing to think about if you are building a rifle. I like to cut the chamber as short as I can or build the magazine a bit bigger so I can have the best of both worlds.

The first thing I do is figure out what the length of my cartridge is with the ogive right up against the rifling. I do this by neck sizing a fire-formed die to my chamber and start the bullet in part way. I will size the neck so a bullet will slide in easily but not move once in place. I then stick it into the chamber of the rifle and slowly close the bolt. Of course I do this with an unprimed case. The bullet is against the rifling with the bolt closed and may be jammed in slightly depending on how much resistance the seated bullet exerts. I don’t worry about this very much because the actual distance the bullet is set back isn’t as important as achieving the exact same distance every time once the most accurate distance is found.

A bullet comparator will help make more accurate measurements of loaded bullets or the model (unprimed uncharged seated bullet to correct size) that I like to create for a reference point. The comparator fits over the loaded round and will give a flatter measuring point than the tip of the bullet. It will usually seat on the ogive which is the point that will contact the lands. By using calibrated competition seating dies, like the ones available from Redding, the shooter can set up the die with the model up to the rifling and then adjust it in whatever increments of set back is desired. Once the best setback is discovered on the range it can be recorded and duplicated. The size can be confirmed accurately with the comparator.

One thing I like about Redding Competition Dies is the adjustment on the sizing die. Achieving the same headspace when sizing brass is important for accuracy also. Once the brass is fired to the chamber I don’t like pushing it back too much when resizing. Whatever push back I give it, I like that I can repeat it with the Redding dies. It also comes in handy when sizing the brass for the first time setting the shoulder right with the chamber. The neck-sizing die has a bushing that can be changed in increments of .001 to get precisely the same tension on the bullet. The standard for the proper size bushing is .001-.002 inches larger than the loaded outside neck diameter. I use a dry lube from Redding to keep the friction down when sizing. It is easily applied with a container of small balls that hold the lubricant.

Another way to get the depth of the rifling is with a Seating Depth Gage from Sinclair International. Measurement is accomplished by dropping a bullet, point first, into the unloaded rifle and inserting the gauge for the first measurement, then doing the same thing with a fired cartridge case. The measurement between the two stops can be measured with a caliper for an accurate length.

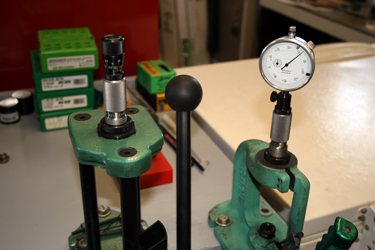

Redding also makes a measurement tool called the Instant Indicator. It is a die that has an adaptor for a dial indicator. Dial Indicators are machinist’s measuring devices accurate to the nearest thousandth on the lines and to the nearest half thousandths cutting between the lines. The indicator also measures from the ogive which should be the most consistent part of a quality bullet. The ogive is the part on the bullet where it comes to the bore diameter. By changing the bushing in the Instant Indicator other calibers can be measured. I have two presses set up side-by-side on my bench. I use them to do two functions at once without using a turret press. When seating competition loads I can instantly check the length while waiting for the power measure to dump another charge. On a turret press it would even work out easier.

I make a model round with the bullet set right out to the lands as mentioned above for a reference point. I set up my seating die to this model and, by using the adjustment, seat the bullet to whatever depth I want to start with. Once the depth is right, the Instant Indicator will affirm that the bullet is precisely the same as the last to the nearest half thousandth. You can also use the Instant Indicator to measure shoulder setback for accurate and repeatable headspace. It is a neat little tool and one of the things it taught me is the most precise tools will have a couple of thousandth variances for a variety of reasons.

I found that the measurements were off a bit when I went to a fresh box of bullets. I was instantly informed of this and made the necessary adjustments to correct the setback. I also found that the dial indicator is so accurate that the shell holder needs to be tighter tolerances. I was using a run-of-the-mill shell holder and sometimes had a couple of thou variances until I put in a tighter holder. Redding makes their shell holders in a variety of sizes to tighten up this area.

Sometimes the shape of the bullet past the ogive to the tip is inconsistent from bullet to bullet just by a little bit. If the seater contacts the bullet in one of these areas it will seat a couple thousandths off perfect. The length to the ogive is what is important so it can be corrected as soon as it is seen in the indicator. The indicator measures off of the ogive. I don’t know if a thousandths is enough to make a difference, but if it can be perfect, why not make it perfect?

Consistency is the key to precision and nowadays there are tools that can give the reloader more precise measurements and repeatability. Depending on the level of precision that is needed to each shooter there is a tool to achieve his or her goals. I find that I enjoy being as precise as I can when measuring critical areas of cartridge reloading. It sure takes hold when the groups relate the effort. If you think it isn’t doing much for your groups at 100 yards, send a few out to 700 yards or better. Some of this fussiness has reduced my long-range groups from a minute to less than one-half minute. GDTM

This article appeared in the July 5, 2010 issue of Gun Digest the Magazine. Click here to learn more about this issue. Click here to load up on a subscription.

Gun Digest Shooter's Guide to Reloading

You’ll benefit from this reloading guide if:

- You want to learn how to reload rifle and pistol ammo

- You need to know the necessary tools required for reloading

- You’d like to learn the benefits of reloading ammo

![Best Concealed Carry Guns In 2024 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)