Wonder what the future of firearms looks like? Solid Concepts might have recently given the world a peek.

The 3D printing service released a video Thursday with what it claims is the first 3D printed metal gun. According to the company’s blog, the .45 ACP 1911 has fired 50 successful rounds, even nailing a couple bull’s eyes at 30 yards.

The process Solid Concepts used to create the 1911 is known as Selective Laser Sintering (a process explained in great detail in the video below).

The amazing part of the printing process is the fact that, outside of some finishing, the company claims the gun was manufactured without any machining. The barrel’s rifling was even printed or as Solid Concepts put it “grown”.

Solid Concepts had a point to prove with the creation of the 1911, more about laser sintering process than the creation of a new firearms manufacturing system:

“The whole concept of using a laser sintering process to 3D Print a metal gun revolves around proving the reliability, accuracy and usability of 3D Metal Printing as functional prototypes and end use products,” says Solid Concepts’ Vice President of Additive Manufacturing Kent Firestone. “It’s a common misconception that laser sintering isn’t accurate or strong enough, and we’re working to change people’s perspective.”

Solid Concepts has come up with a compelling firearm, much more so than some of the first iterations of 3D printed guns (such as the Lutz Liberator). But unlike those early versions, metal printing is presently far outside the price range of the 3D printing hobbyist.

But perhaps someday…

Recommended D-I-Y Resources

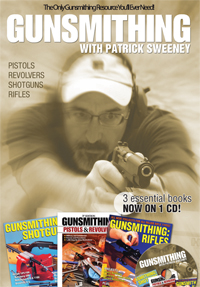

Gunsmithing with Patrick Sweeney CD

Gunsmithing with Patrick Sweeney CD

Did you find the 3D printed gun article interesting? Than you're certain to find Gunsmithing with Patrick Sweeney a useful read. The CD is the compilation of three books by Sweeney: Gunsmithing: Pistols & Revolvers; Gunsmithing: Rifles; and Gunsmithing: Shotguns. The reference is perfect if you are looking for a troubleshooting guide for your firearms, want to find the right methods of cleaning and repairing your firearms, or if you are interested in becoming a gunsmith.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)

Very interesting. Metal fabrication was really changed since my production machinist days. Like any new technology it’ll be tested and tweeked to fit different applications. I remember the squealing and angst when Ruger introduced the M77 rifle and its cast receiver. Then the moans about Dan Wesson using sintered metal for the hammer & trigger on its revolver. Then “plastic” guns. More recently the howls about MIM. MIM parts are so common on guns and the “steel and wood” crowd hasn’t a clue. If they only knew they’d faint! LOL

It remains to be seen how long these parts will last before they crack and fail or mushroom out.