|  |  | |

|

Basic Equipment: Getting What You Need

Basic Equipment: Getting What You Need

One way to enter the water, as it were, is to get acquainted with other reloaders and see what they use and don’t use, and quiz them on the whys and wherefors of their equipment. Ask a friend if you can try his equipment. This way you can get a feel for the tools, how they work, and begin to come to some decisions regarding what you might like and what you find difficult or unnecessary.

The reloading bench is the foundation of your work area. There is no standardized design, and it may well serve a dual purpose as a kitchen counter on which reloading tools are temporarily mounted. If you must use a temporary surface of this type, your reloading press and sizer/lubricator should be permanently mounted on a solid 2×6 or heavier plank that can be securely attached to the counter top with C-clamps. The counter must have a solid top since the levering force exerted on the bullet sizer and the loading press can pull the counter top loose.

If you have the space, a solid desk or workbench arrangement is best. General requirements are that it have enough weight or be attached to the floor so that it will not rock back and forth in use. It should be solid enough that the top will not pry loose under the stress of cartridge and bullet sizing. Whether or not it is to be a thing of beauty depends on how much of the public will view it, in a dining room or corner of an apartment, or if it will stay in a garage or basement area. If ammunition and powder are to be stored in the same area, the bench should in a spot that is climate controlled. It should have at least one large drawer and be close to shelving or cabinets where bullets, primers, powder, cases, loading manuals, etc., can be located within easy reach. The top should be smooth and free of cracks, holes and splinters.

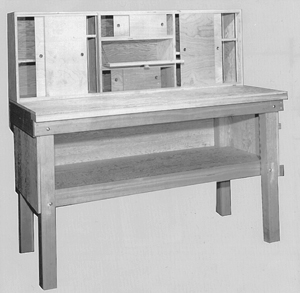

While you can build a bench of your own design out of whatever scrap lumber you have at hand, an easier way is to use plans from the National Reloading Manufacturers Association. (That organization is now inactive, but you can go to Chapter 18 where your editor revisits those plans, and actually gives you the complete plans right in this book.) If you’re handy with tools, you can buy all the components from your local lumber yard or building materials store for around $100 and assemble it yourself.

The NRMA bench is heavy, solid and able to support all manner of tools and presses, The plans have been around for more than 20 years, and thousands of reloaders have built them. The plans call for heavy dimension lumber and plywood, so build it where you will use it.

Once you have your bench, the next step is to choose the basic reloading tool, the heart of your operation–the press. Before parting with any money, it is best to start with the maximum amount of experience and knowledge. This returns to the above-mentioned issues of speed, economy and precision. Your first question should be: Am I going to load for pistol, rifle or both? Shotshell reloading requires it’s own special loading equipment and will be dealt with later. If the answer is to reload both handgun and rifle cartridges, then you will want to buy a press that is intended for rifle cartridges that will do handgun ammunition as well.

Economy Versus Speed

The most basic type of bench-mounted loading press is the O-frame or C-frame press, so called because the frames are shaped like these letters. Both are rugged and simple. They are also referred to as single-stage presses since they mount a single loading die in the top. Each operation–decapping and sizing, neck expanding and bullet seating–requires that the die be unscrewed and the next die screwed in place for each operation. Most reloaders perform each operation in batches, so you don’t spend all your time changing dies. The manufacturers promise a production rate of about 100 finished rounds per hour.

Similar to these are the arbor presses, which mount a single die in the bottom. Arbor presses require a special straight-line type of die that is not compatible with the top-mounted variety used in standard presses. The price range and speed are about the same. Arbor presses are small and compact, and have the advantage of being on a flat base and not requiring permanent bench mounting. This makes them handy to take to the range where ammunition can be fabricated while you shoot. In addition to instant gratification, this portability saves time and material put into long runs of test ammunition.

More expensive and faster are the turret and H-frame machines that allow a full three-die set to be mounted along with a powder measure. All dies are in place and the cartridge is moved from one station to the next, or the turret is rotated to bring the next die into position. Production is estimated at 200 rounds per hour, but the price is higher.

Near the top end, short of buying an ammunition factory, are the progressive loaders. These are semi-automated machines with feed tubes and hoppers that are filled with cases, bullets, primers and powder. Once the various feeding devices are filled, the operator simply pulls a handle and manually feeds one component, usually bullets or cases, inserting them into a slot on a revolving plate, and the machine does the rest, moving the case from station to station. The finished rounds come popping out at the end of a full plate rotation cycle and are collected in a convenient bin. Production rates are from about 500 rounds per hour to 1200. Plan to do a lot of shooting if you invest in one of these. You should also plan to have plenty of space since a progressive stands better than 2 feet high and weighs up to 50 pounds.

Speed Versus Precision

The Dillon RL 1050 will load 1000 to 1200 rounds per hour. A progressive loader of this sort represents a sizable investment and is definitely not for beginners. |

All of the presses mentioned will produce high quality, precision ammunition, or at least as precise as you make it, since quality control is up to the operator. Careful adjustment, precise measurement, and inspecting every step in production are your job, and if you do it well, the results will show in the finished product.

Progressive loaders are designed more for speed than precision. In the case of handgun ammunition where benchrest accuracy is not expected, they are the best investment for a shooter who really burns a lot of ammunition.

These are also purchased by clubs, police departments and professional reloaders who sell their ammunition. While progressives churn out tremendous quantities of ammunition, they generally require a fairly complicated set-up period, and if there is a change of caliber of ammunition, this can mean a different set of feed tubes and plates as well as dies. Because they are complicated, progressives require more tinkering and cleaning to keep them running smoothly. Automation of the process means you depend on the machine to do it right every time. That doesn’t always happen.

Precision Versus Economy

As mentioned above, precision and economy lie mainly with the single-die and turret/H-frame (multi-station) machines. Progressives only pay when there is a demand for high-volume production of one caliber at a time. The price differential between the single-stage and turret/multi-station machines is close enough that it is probably worth the extra money to invest in the latter if you are going to do more than a very modest amount of reloading. They have the advantage of holding a full die set and a powder measure.

This means the dies are seated and adjusted once, for the most part, unless you are reloading a number of calibers. The production edge will be noticed as the amount of ammunition you make increases. For a shooter reloading a single caliber––mainly for hunting––someone who does not do a lot of practice and may assemble no more than 200 to 2000 rounds a year––the best buy would be the simple, reliable O- or C-frame machine. It will do the job.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)