At GunDigest, we independently review products. However, we may earn a commission when you purchase through links on our site. Learn More

The Basics of Selecting Reloading Powders

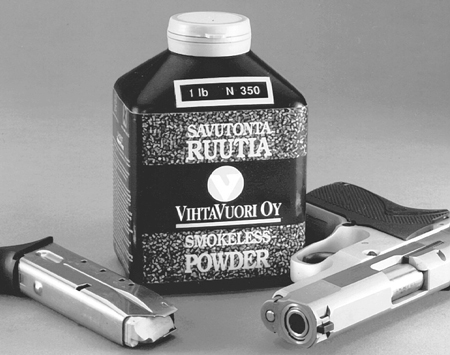

Modern reloading powders are divided into three basic types on the basis of their use. These are pistol, shotgun, and rifle powders. But for the beginning reloader, these are but a starting point in selecting the right powder for the desired load.

Reloading powders for pistols are generally of the fast-burning double-base type for use in short-barreled guns. Shotgun powders are also fast burning and double-base, designed to burn completely under low pressures. Rifle powders are generally slower burning to accelerate a rifle bullet down a long barrel with maximum velocity while producing minimum pressures.

In point of fact, many reloading powders for pistol use are quite suitable for shotguns and vice versa. Some slower burning pistol and shotgun powders will also work well for reduced velocity rifle loadings, where a light bullet and light powder charge are used.

Before buying a quantity of powder, it is a good idea to consult one or more reloading guides to see what is offered and what looks to be the best selection for your particular gun or guns. Then, buy a small can to develop your loads. If that powder proves suitable for your uses, it’s a good idea to go ahead and buy larger amounts.

Storage and Handling of Reloading Powders

Modern powders are almost completely gelatinized, making them less affected by dampness. In fact, a sample of Laflin & Rand (later Hercules, now Alliant) Unique powder was placed in storage under water in 1899 to test its viability. It was last tested in 1996. It will be tested again in this century when it is expected to continue performing as well as when it was made.

As smokeless powders deteriorate, they generate small amounts of nitric acid. Stabilizers are added to these powders to absorb acid byproduct. Most reloading powders have fifty or more years of life before the stabilizers are used up and nitric acid begins to leach out of the nitrocellulose, leaving plain cellulose and reducing the efficiency of the powder. Occasionally powder will deteriorate owing to acid residue that was not properly washed out in the manufacturing process. Such powder will take on an unpleasant acidic smell and a brown dust looking very like rust will appear in the powder.

Powder in this condition will not shoot well, giving poor ignition and low power. It should be disposed of. Metal cans containing powder will sometimes rust on the interior, producing a very similar-appearing dust, but without the characteristic odor. This does not harm the powder and can be removed by dumping the powder on a flat piece of bed sheet, spreading it evenly, and gently blowing off the dust.

The powder should then be placed in another container. An empty plastic powder bottle is good so long as it is clearly marked as to what it is. It is a good idea to mark containers of powder with the date of purchase and then use the oldest first. Opened containers of powder should be checked at least every year for signs of rust or deterioration if they are not being used. Sealed containers should be left sealed until they are to be used. Alcohols and occasionally camphor are added to stabilize burning characteristics. Powder containers should be kept tightly closed to keep these volatile additives from evaporating into the air.

Smokeless powder is quite safe to handle because it is not sensitive to shock. The main caution that must be taken is to keep it from open flame or heat. It will ignite above 400 degrees F. Shelf storage is suitable, preferably on a second floor where temperatures remain most stable. Powder should never be stored in heavy closed metal containers that could act as bombs in case of a fire. Never have more than one container of powder open at a time. If there is a fire this – hopefully – limits it to one can.

Smokeless powder is toxic if ingested because the nitroglycerin component causes heart irregularity. British soldiers in WWI chewed smokeless powder from rifle cartridges to cause a brief though severe illness to get off the line, until medical authorities discovered this practice. Children have a tendency to taste things; smokeless powder should not be one of them.

Loading Density

Various combinations of bullets and powder charges can be assembled to achieve the same velocity. Some are going to be more accurate than others. Various manuals will often indicate loads that gave the best accuracy in particular guns. This is usually the best place to start developing a load, although such a combination will not necessarily be the best performer in your gun.

Generally speaking, when selecting a powder there are a few rules of thumb worth following. Larger-capacity rifle cartridges, with heavy bullets, generally perform best with slow-burning powders. For best accuracy, a powder charge that fills the case with little or no air space tends to give better accuracy than a small charge that can shift position in the case. Shooters using reduced loads, particularly in rifles, get better results by tipping the barrel skyward before each shot to position the powder to the rear of the case.

This can also be achieved by using wads or wads plus fillers to fill up the space, but the results are usually not as good. A filler wad should never be placed over the powder with an air space between it and the bullet. The space must be filled entirely. If there is a space, the wad will come slamming against the base of the bullet with enough force to make a bulged ring in the case and often in the chamber of the gun!

Compressed Loads

Never compress powder in a cartridge case unless such a load is recommended in a reloading manual. Compressed loads should never be more than 10 percent above the case capacity. A compression of more than this often leads to lower than desired velocities. If the compression is excessive it can actually bulge the case or cause the case to stretch in the loading process, resulting in a cartridge that is oversize or too long and will jam the gun.

This article is an excerpt from ABCs of Reloading, 8th Edition.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.